Description

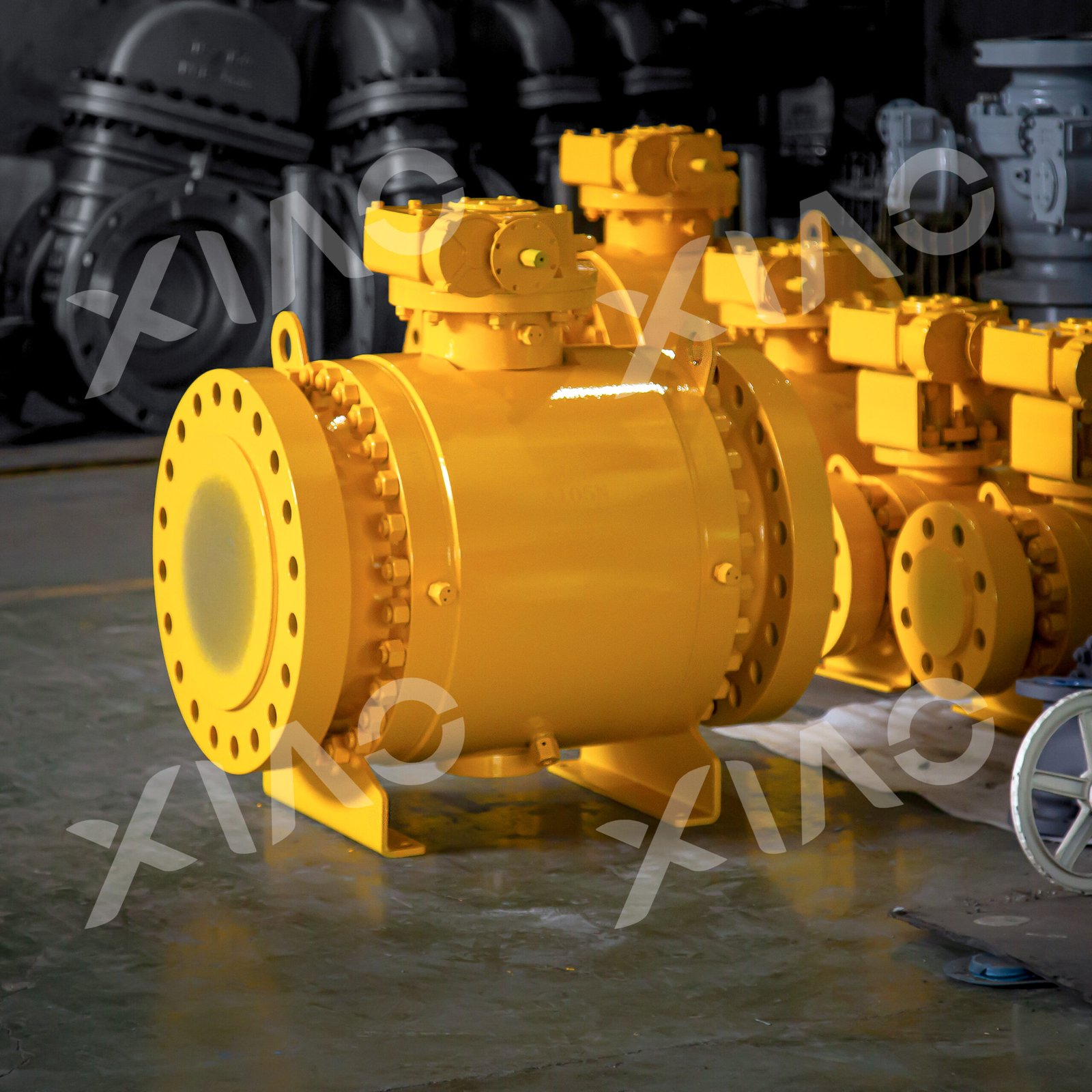

Mould Example: FTQ347H-300LB ~ FTQ347H-2500LB

Unbeatable Forged Trunnion Ball Valves

Built for Extreme Conditions, Leakage Rate <0.0001%

Key Specs

| Pressure: Class 150~2500LB |

| Size: 2″~48″ |

| Temp: -196°C~350°C |

| Material:ASTMA105/F304/F304L/F316/F316L |

Technical Specs

| Parameters | Specification |

| Pressure Rating | Class 150~2500LB |

| Media | Natural Gas/LNG/Sour Gas |

| Connection | Flange/Butt Weld/Socket Weld |

| Fire Safe | API 607/6FA Certified |

| Feature |

|---|

| Size: 2″ – 24″ |

| Class: 150~2500Lb |

| Three Pieces Forged Steel Body |

| Trunnion Mounted Ball, Full & Reduced Bore |

| Anti-static Device |

| Blow-out Proof Stem |

| Double Block and Bleed |

| Fire Safe Design |

| Emergency Sealant Injector, Vent Valve |

| Vent valve, drain valve |

| Lifting Lugs & Supporting Feet (8″ & Larger) |

| Specification | Standard |

|---|---|

| Design | ASME B16.34 / API 6D |

| Face to Face | ASME B16.10 / API 6D |

| End Flange | ASME B16.5 |

| B/W End | ASME B16.25 |

| Test | API 6D |

| Fire Safe Test | API 607 / API 6FA |

| Special | NACE MR-01-75 |

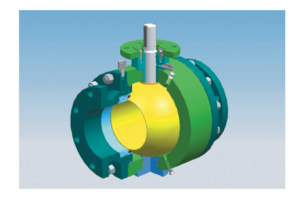

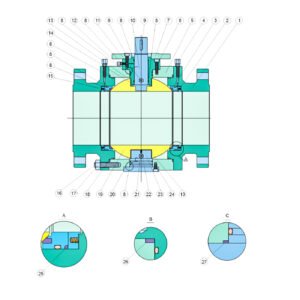

Cross-Sectional Diagram of a Trunnion Mounted Ball Valve

This technical illustration showcases the internal structure of a trunnion mounted ball valve, highlighting its major components and how they interact to control fluid flow. The central cross-section reveals key elements such as the ball, trunnion, seats, stem, and seals. The labeled parts (1–27) correspond to specific mechanical elements, which are crucial for the valve’s operation, sealing, and support. Insets A, B, and C provide magnified views of critical sealing areas for better clarity. This diagram is ideal for engineering reference, maintenance guidance, or instructional use.

MATERIAL SPECIFICATIONS

| No. | Part | Material |

| 1 | Bonnet | ASTM A105, A182-F304, F316, F316L, F304L, F51 |

| 2 | Seat Spring | Inconel X-7505, SS304, SS316 |

| 3 | Seat | PTFE, RPTFE, PEEK, PPL |

| 4 | Seat Injection | 1020+ZN, A182-F304, F316, F316L |

| 5 | Body | ASTM A105, A182-F304, F316, F316L, F304L, F51 |

| 6 | Screw | ASTM A193-B7, B9 |

| 7 | Top Flange | ASTM A105, A182-F304 |

| 8 | O-ring | NBR, Viton |

| 9 | Key | 1045, A182-F304, F316, F316L, F304L |

| 10 | Stem | A105+ENP, A182-F6, F304, F316, F316L, F304L, 17-4PH, F51 |

| 11 | Vent Valve | 1020+ZN, A182-F304, F316, F316L |

| 12 | Stem Injection | 1020+ZN, A182-F304, F316, F316L |

| 13 | Sliding Bearing | Stainless Steel+PTFE, SS316+PTFE |

| 14 | Thrust Washer | PTFE |

| 15 | Seat Ring | A105+ENP, A182-F6, F304, F316, F316L, F304L, F6, F51 |

| 16 | Stud | ASTM 193-B7, B7M, B8, B8M |

| 17 | Nut | ASTM 194-2H, 2HM,8, 8M |

| 18 | Body Gasket | PTFE, SS304+Graphite, SS316+Graphite |

| 19 | Ball | A105+ENP, A182-F6, F304, F316, F316L, F51 |

| 20 | Lower Gasket | PTFE |

| 21 | Drain Valve | 1020+ZN, A182-F304, F316, F316L |

| 22 | Antistatic Spring | Stainless Steel, SS316 |

| 23 | Trunnion | A105+ENP, A182-F6A, F304, F316, F316L, F304L, F51 |

| 24 | Screw | ASTM A193-B7, B8 |

| 25* | Seat Sealing | Graphite |

| 26* | Gland Gasket | SS304+Graphite |

| 27* | Bottom Cover Gasket | SS304+Graphite |

Industry Solutions

LNG Cryogenic: -162℃ leakage-free, BS 6364 certified

Sour Gas Fields: H₂S resistant, NACE MR0175 compliant

Hydrogenation Units: 100,000 cycles at 550℃

Why Us?

Zero-Leakage Guarantee

Dual piston-effect seals + Emergency grease injection

Fire-Safe Certified

API 607/6FA certified, safe shutdown even in fires

3X Longer Life

50% harder forged body, 20-year maintenance-free

48 Hour Delivery:2000+ models in bonded warehouse

Lifetime Support: Free 3D models & installation videos