Description

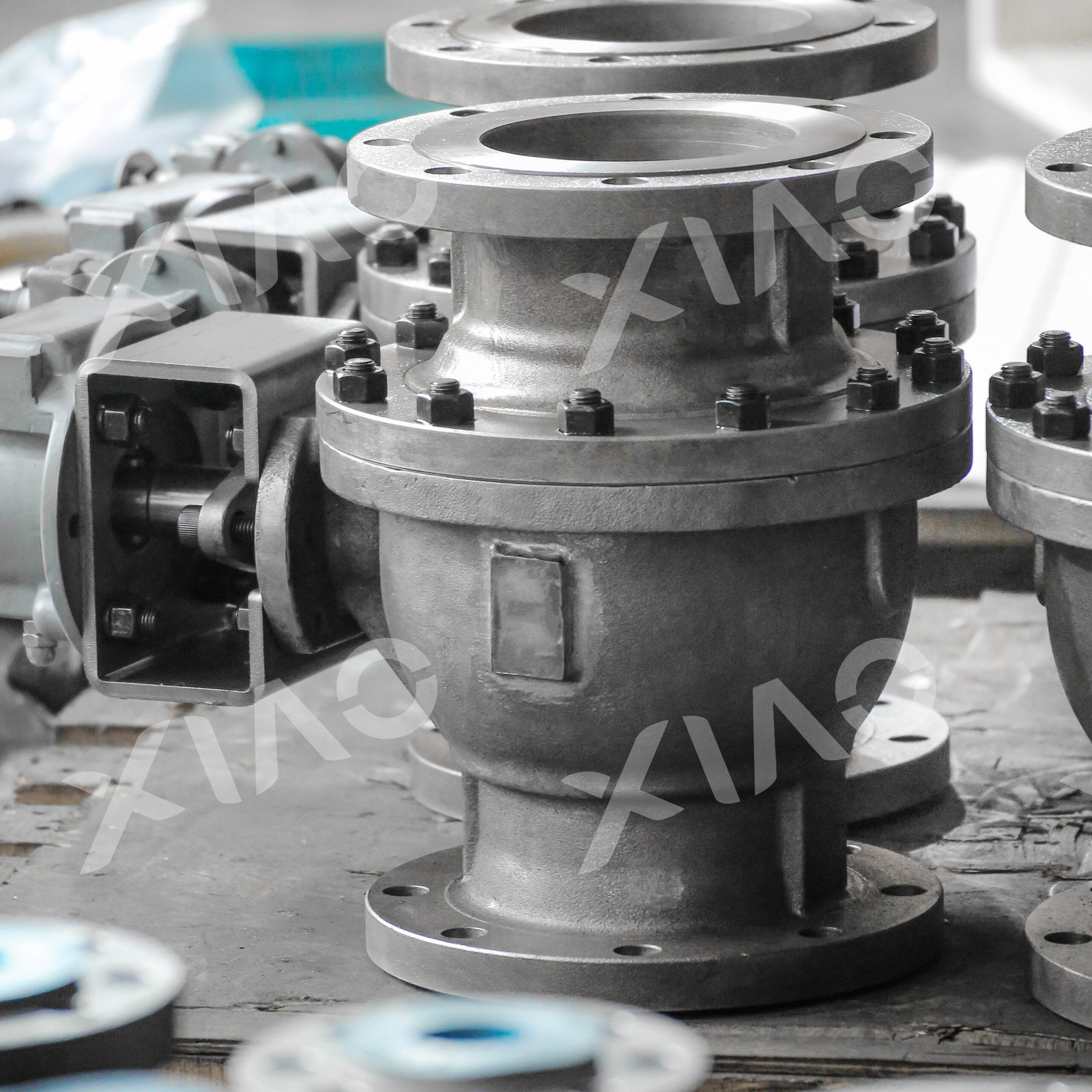

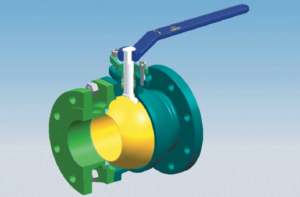

Cast Floating Ball Valve Series

Material Types:

(ASTM A216 WCB/WCC)

Cast Carbon Steel (ASTM A216 WCB/WCC)

(ASTM A351 CF8/CF8M)

Cast Stainless Steel (ASTM A351 CF8/CF8M)

Product Overview

Our cast floating ball valve series combines precision sand-casting technology. Carbon steel models suit general water/steam systems, while stainless steel variants are engineered for corrosive media. Certified to API 6D/ISO 9001 with soft-seal (PTFE) or metal-seat options, covering diverse applications from -196°C cryogenic to 450°C high-temperature environments.

Technical Specifications

| Parameters | Carbon Steel | Stainless Steel |

| Pressure Rating | Class150~300 LB (PN16~PN40) | Class150~600 LB (PN16~PN100) |

| Connection | (RF/FF | (RF/RTJ) |

| Seat Material | PTFE/RPTFE/ | PTFE |

Industry Solutions

Petrochemical:

Carbon steel: Steam tracing line control

Stainless: Concentrated sulfuric acid transfer (Hastelloy trim optional)

Food & Pharma:

316L stainless, Ra≤0.8μm mirror finish, FDA compliant

Global Certifications

API 607 Fire Safe / NACE MR0175 H₂S Resistance / EU CE-PED Directive

Service Commitment

15-year warranty for carbon steel, lifetime limited warranty for stainless

Free Material Test Certificates (MTC)

Conversion Optimization Tips

Add “Material Selector Wizard” interactive tool

Bilingual PDF catalog with bookmarked navigation

“Click to watch SS valve application in Saudi desalination plant”

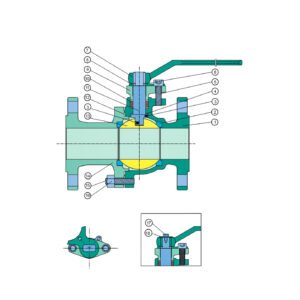

Cross-Sectional Diagram of a Flanged Ball Valve with Labeled Components

This diagram illustrates the internal structure and working parts of a flanged ball valve. Each numbered label corresponds to a specific valve component, offering insight into its construction and function. The ball valve is operated by a lever handle and includes features such as the ball, seat, stem, and various seals and fasteners, allowing precise flow control and easy maintenance in piping systems.

MATERIAL SPECIFICATIONS

| No. | Part | Material |

| 1 | Body | A216-WCB, A352-LCB, A351-CFB, CF8M, CF3, CF3M |

| 2 | Seat | PTFE, RPTFE, PEEK, PPL |

| 3 | Antistatic Spring | Stainless Steel, SS316 |

| 4 | Thrust Washer | PTFE |

| 5 | Screw | ASTM A193-B7, B8 |

| 6 | Retainer | Carbon Steel |

| 7 | Lever | A216-WCB |

| 8 | Limited Plate | 1015+Cr, Carbon Steel+Cr |

| 9 | Gland Flange | A216-WCB, A351-CF8 |

| 10 | Packing | PTFE, Graphite |

| 11 | Stem | ASTM A105+NIP, A182-F6, F316 |

Features

| Feature | Description |

| Size | 1/2″ – 10″ |

| Class | 150 ~ 600LB |

| Body Type | Two Pieces Cast Steel Body |

| Ball Type | Floating Ball, Full & Reduced Bore |

| Anti-static Device | Included |

| Stem | Blow-out Proof Stem |

| Fire Safe Design | Yes |

| Emission | Low Emission |

Specifications

| Specification | Standard |

| Design | ASME B16.34 / BS 5351 |

| Face to Face | ASME B16.10 |

| End Flange | ASME B16.5 |

| BW End | ASME B16.25 |

| Test | API 598 / BS 6755 |

| Fire Safe Test | API 607 / API 6FA |

| Special | NACE MR01-75 |