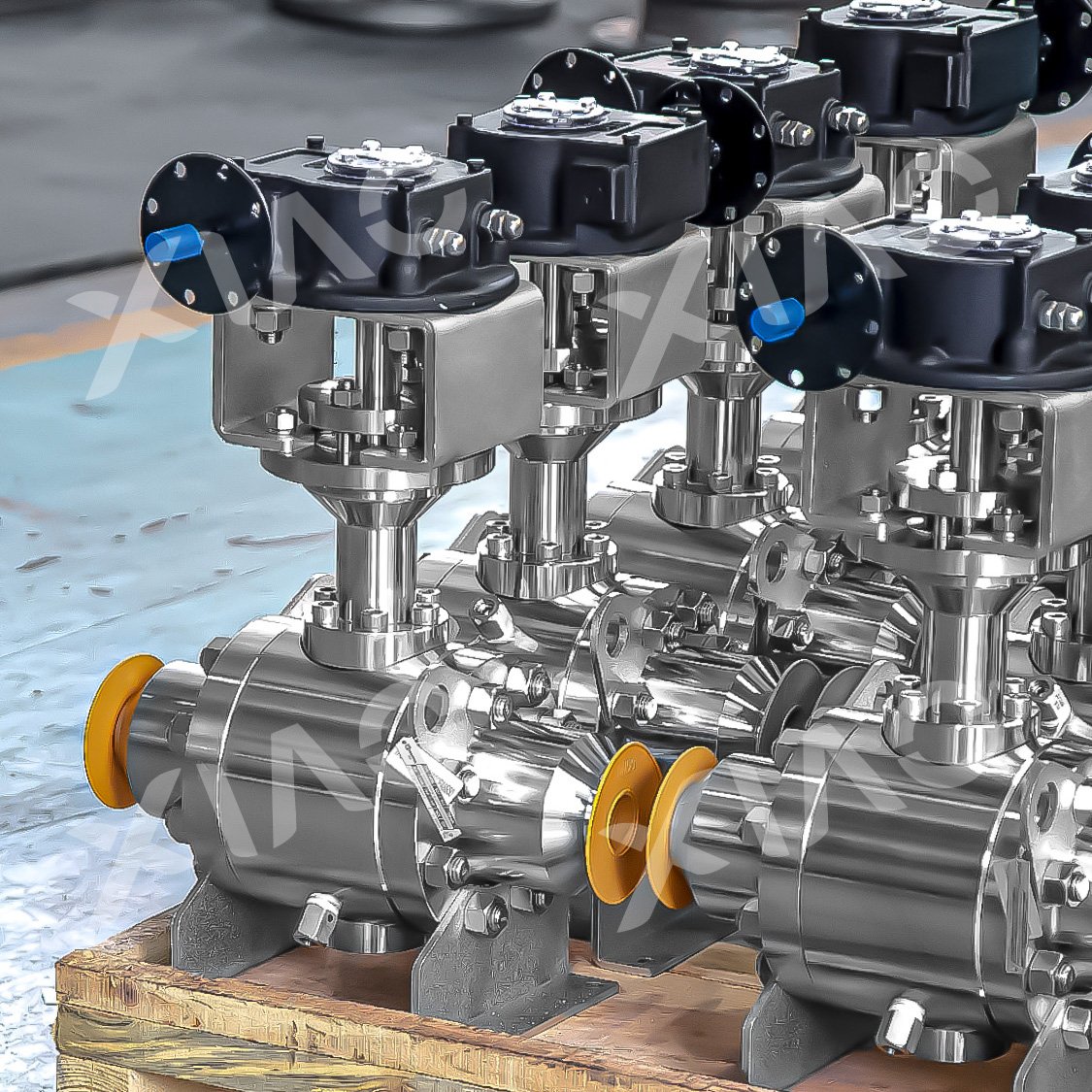

Description

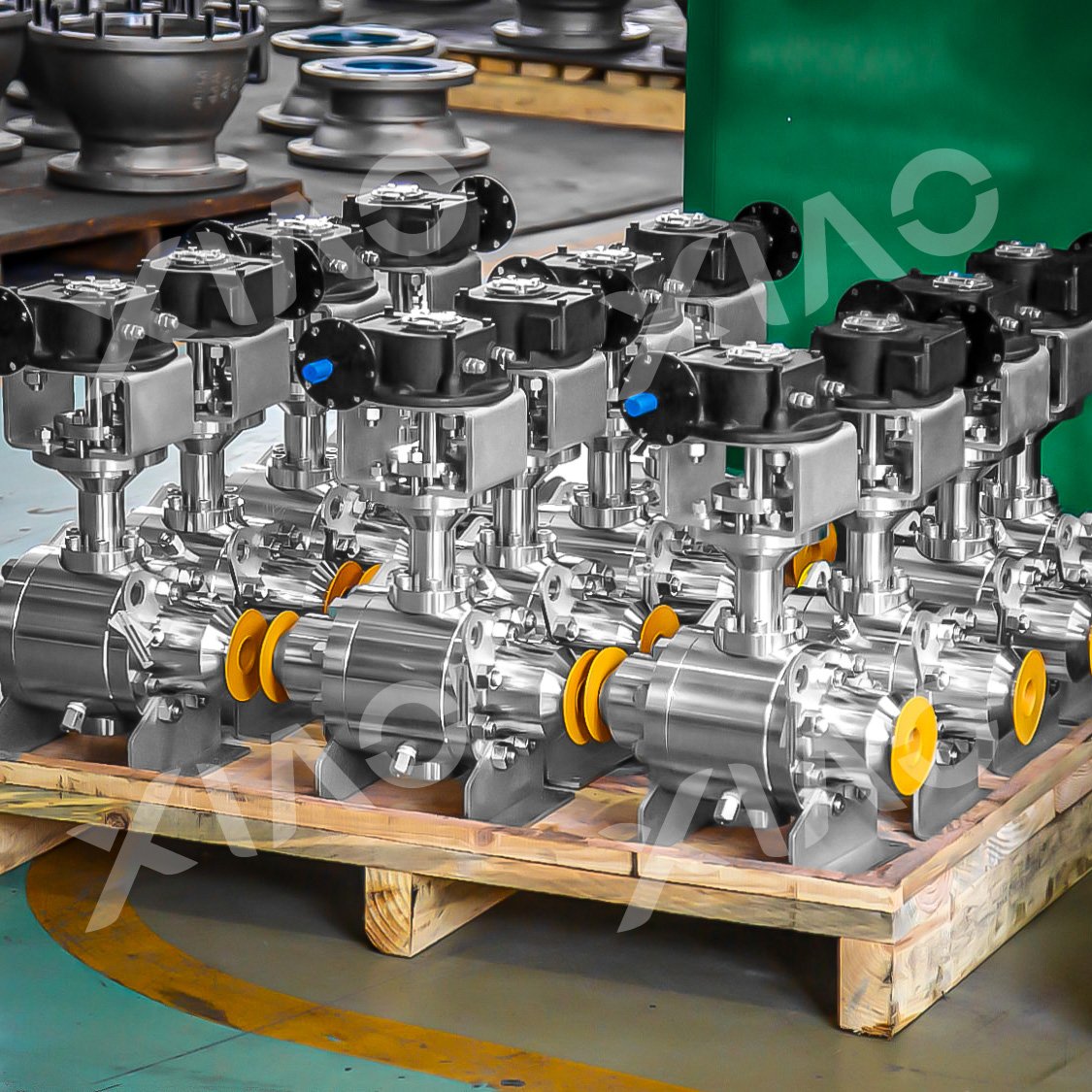

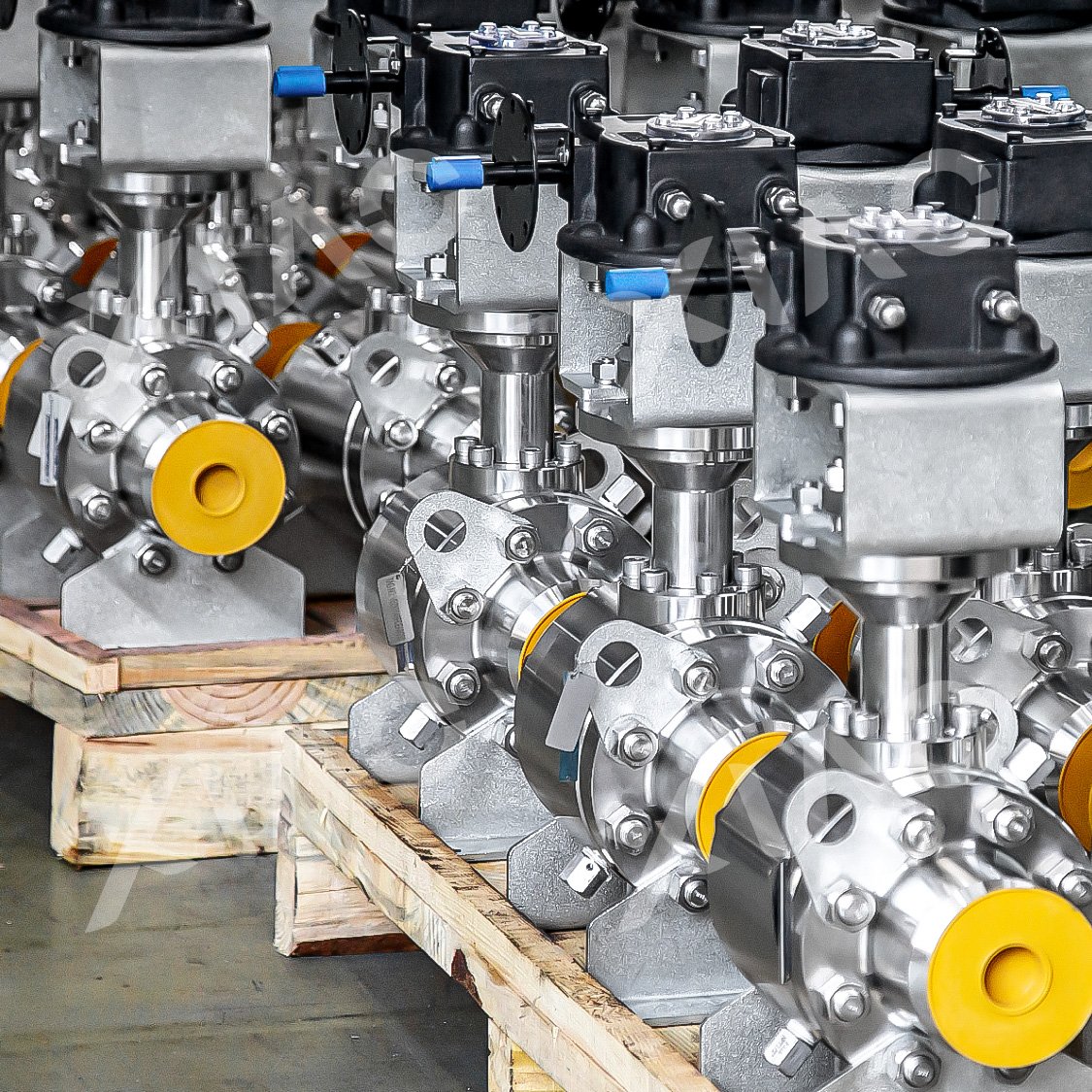

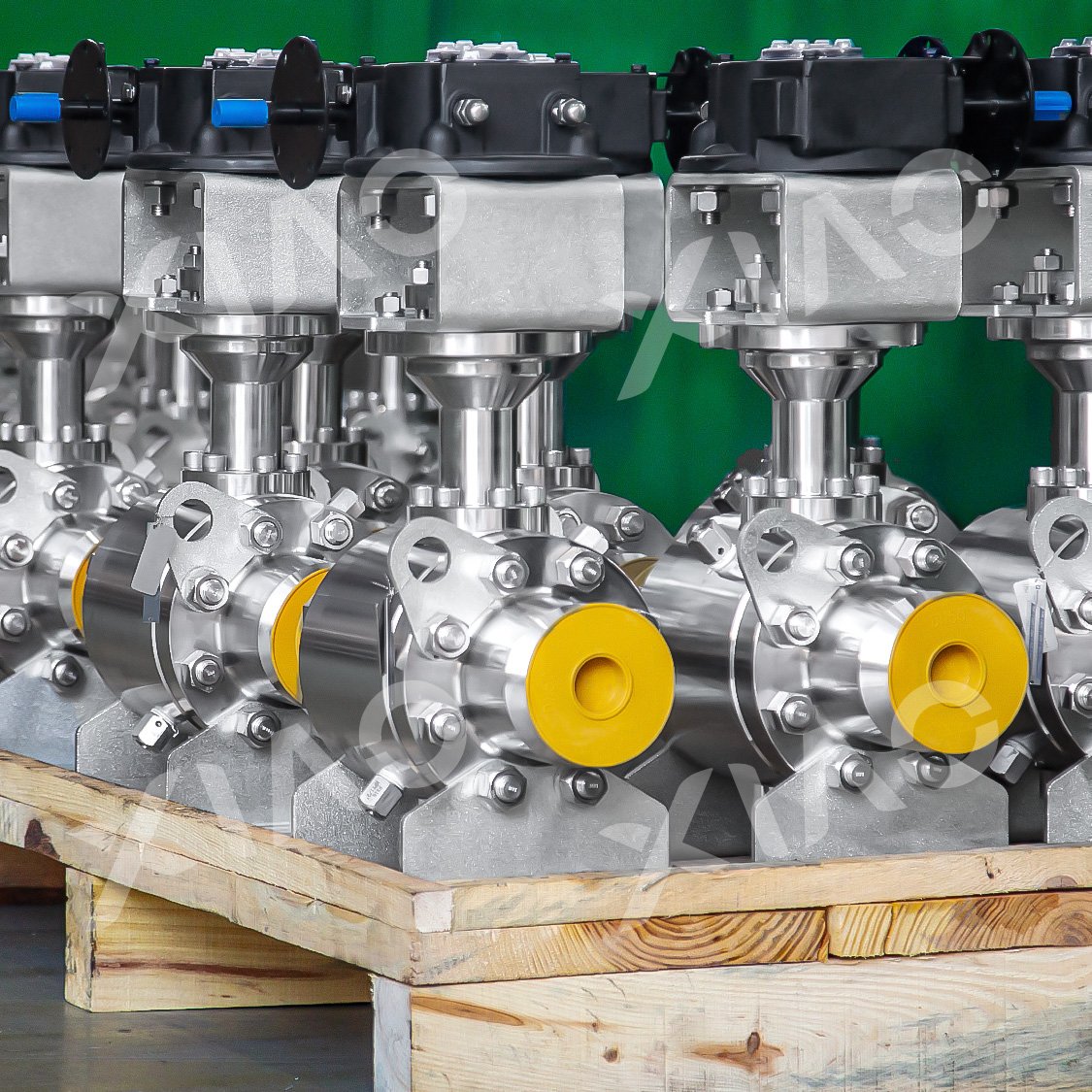

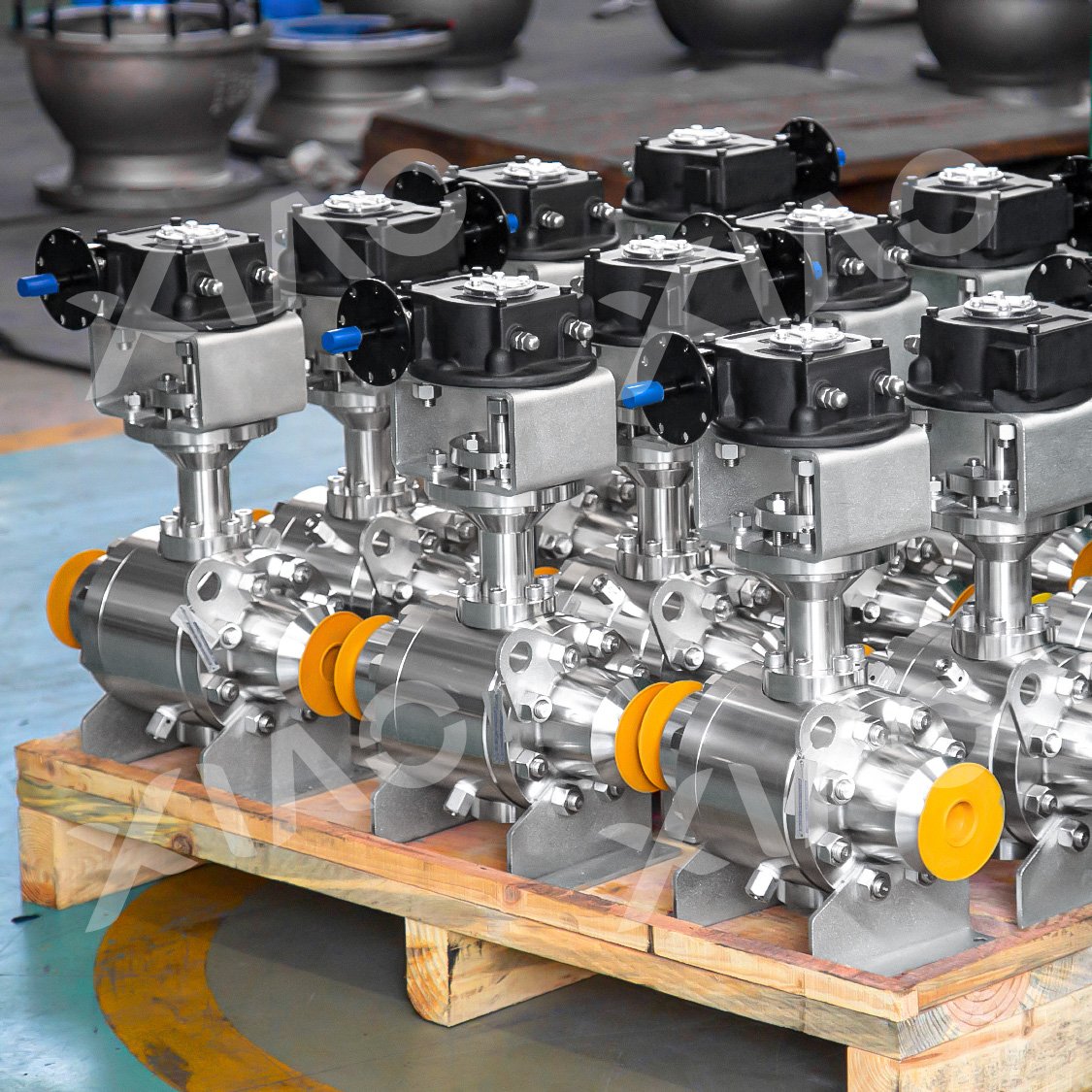

Crafted from premium forged steel and certified to API 6D/CE/ISO standards, our Forged Steel Floating Ball Valve is engineered for high-pressure, high-temperature, and critical applications. The floating ball structure ensures bidirectional zero-leakage sealing under medium pressure, making it an ideal solution for fluid control in oil & gas, chemical, and power industries.

Superior Material Performance

Forged Body: ASTM A105/A182 forged steel, 30% higher pressure resistance (PN16-PN420)

Hardened Treatment: Ball surface hardness HRC60+, 50% longer service life

Advanced Sealing System

Bidirectional Zero Leakage: API 598 compliant, PTFE/graphite sealing

Fire-Safe Design: API 607 fire-test certified

Efficient Operation

Low Torque: 40% reduced operating torque, multi-actuation options

Visual Indicator: Clear position marking, optional limit switches

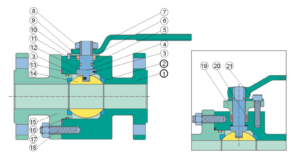

Detailed Cross-Section Diagram of a Flanged Ball Valve Assembly

This technical illustration shows a cross-sectional view of a flanged ball valve assembly, highlighting all critical internal and external components. The diagram clearly labels each part, including the valve body, stem, ball, seats, seals, and handle mechanism. The inset provides an enlarged view of the stem sealing arrangement, offering a closer look at the packing gland and spring elements that ensure a leak-free seal during operation.

Key features include:

-

A full-bore design allowing unrestricted flow.

-

A robust handle mechanism for manual control.

-

Precision-seated ball for reliable sealing and minimal torque.

-

Secure bolted flange connections.

-

Detailed component numbering for easy identification during assembly, maintenance, or replacement.

This image is ideal for engineers, maintenance personnel, or procurement teams seeking a clear understanding of industrial valve construction and operation.

Technical Specifications

| Parameters | English Details |

| Size | DN15~DN300 (½”~12″) |

| Pressure Rating | PN16~PN420 / Class150~2500LB |

| Temperature | -29℃ ~ +200℃ (Customizable to +425℃) |

| Connection | Flange/Threaded/Welded (SW,BW) |

| Body Material | ASTM A105/A182 F304/F316 |

| Feature |

|---|

| Size: 1/2″ – 4″ |

| Class: 150~2500Lb |

| Three & Two Pieces Forged Steel Body |

| Floating Ball, Full & Reduced Bore |

| Anti-static Device |

| Blow-out Proof Stem |

| Fire Safe Design |

| Low Emission |

| Specification | Standard / Code |

|---|---|

| Design | ASME B16.34 / BS 5351 |

| Face to Face | ASME B16.10 |

| End Flange | ASME B16.5 |

| Bw End | ASME B16.25 |

| Test | API 598 / BS 6755 |

| Fire Safe Test | API 607 / API 6FA |

| Special | NACE MR-01-75 |

| No. | Part | Material |

|---|---|---|

| 1 | Body | ASTM A105+ENP, A182-F6, F304, F316, F316L, F304L, F51 |

| 2 | Seat | PTFE, RTPFE, PEEK, PPL |

| 3 | Antistatic Spring | Stainless Steel, SS316 |

| 4 | Stem | A105+ENP, A182-F6, F304, F316, F316L, F304L, 17-4PH, F51 |

| 5 | “O”-Ring | NBR, Viton |

| 6 | Limited Plate | 1015+Cr, Carbon Steel+Cr |

| 7 | Lever | A216-WCB, 1025+Cr |

| 8 | Fix Nut | Stainless Steel |

| 9 | Backup Ring | ASTM A182-F304, F316 |

| 10 | Packing | PTFE, Graphite |

| 11 | Positioning Pin | Stainless Steel |

| 12 | Thrust Washer | PTFE |

| 13 | Gasket | PTFE, Graphite |

| 14 | Ball | ASTM A105+ENP, ASTM A182-F6, F304, F316, F316L, F51 |

| 15 | Bonnet | ASTM A105+ENP, A182-F6, F304, F316, F316L, F304L, F51 |

| 16 | “O” Ring | NBR, Viton |

| 17 | Stud | ASTM A193-B7, B7M, B8, B8M |

| 18 | Nut | ASTM A194-2H, 2HM, 8, 8M |