Description

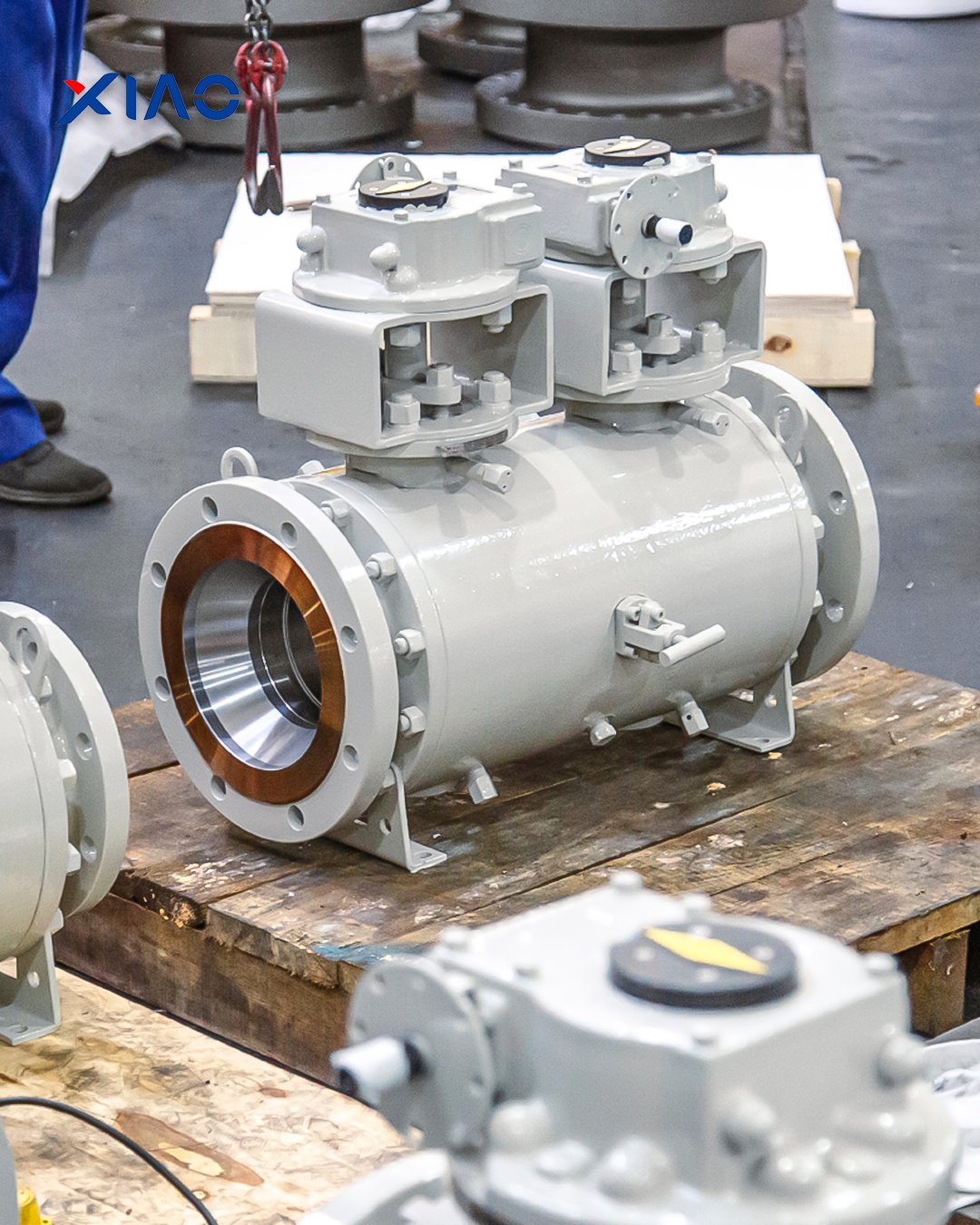

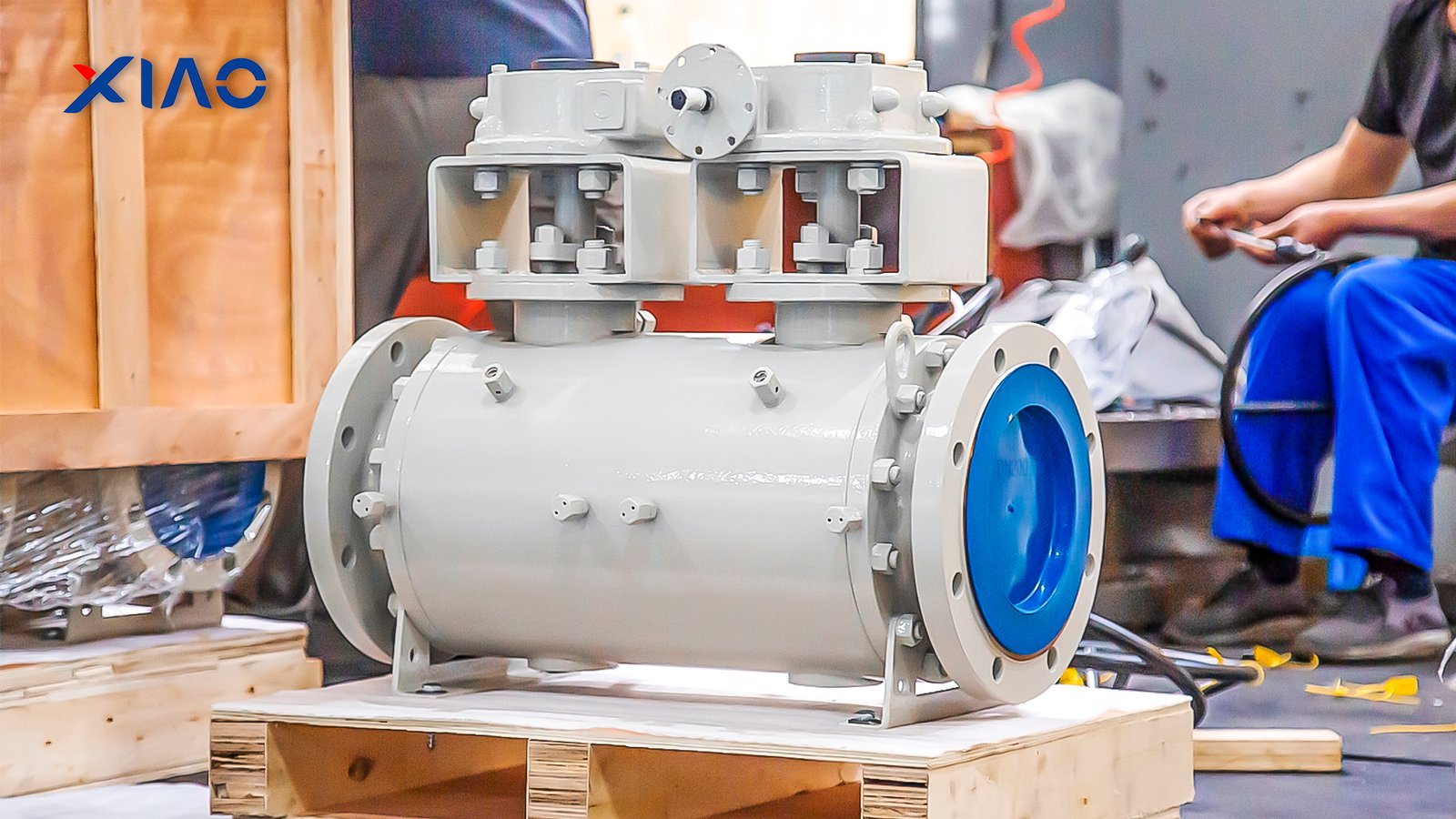

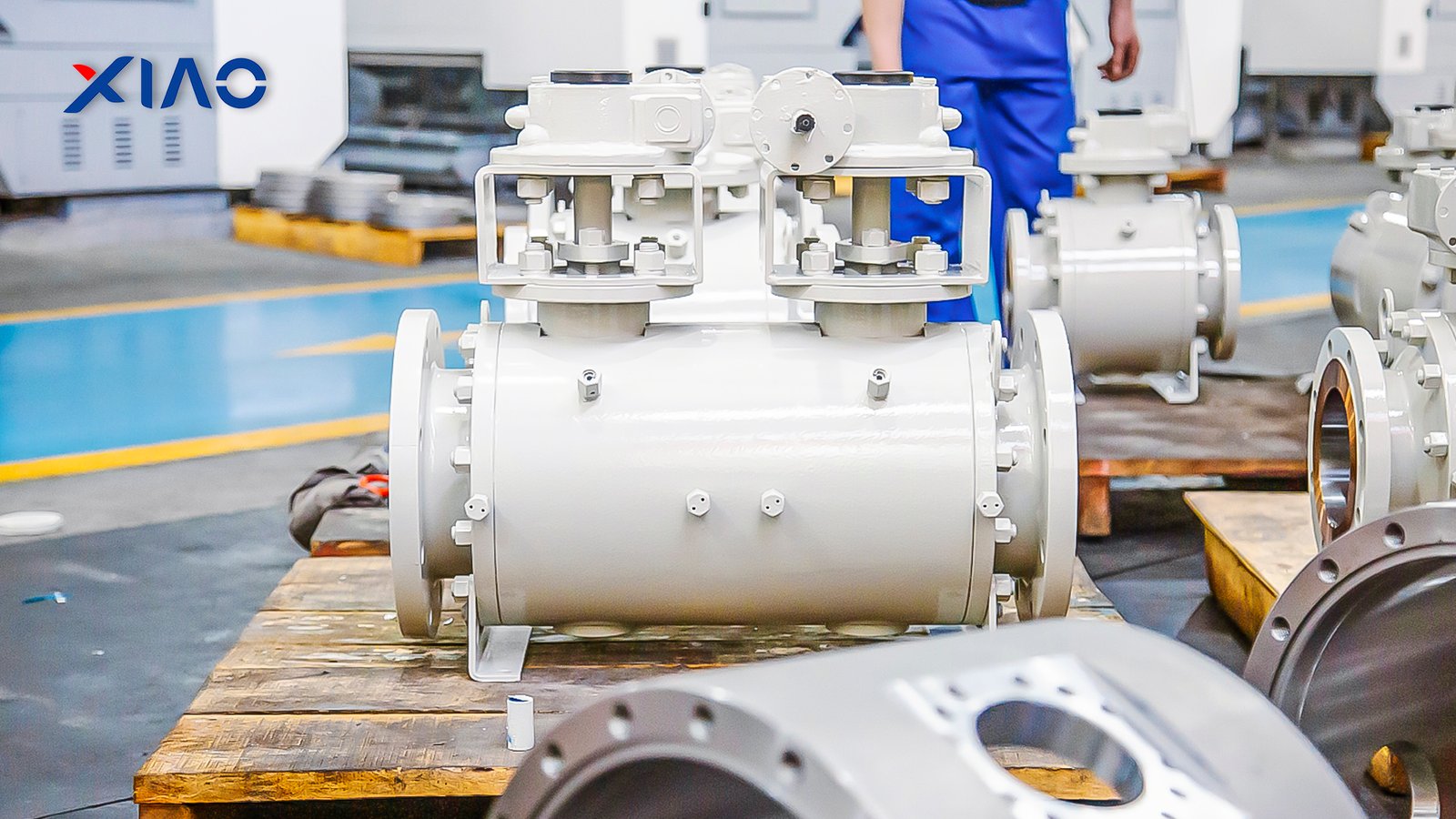

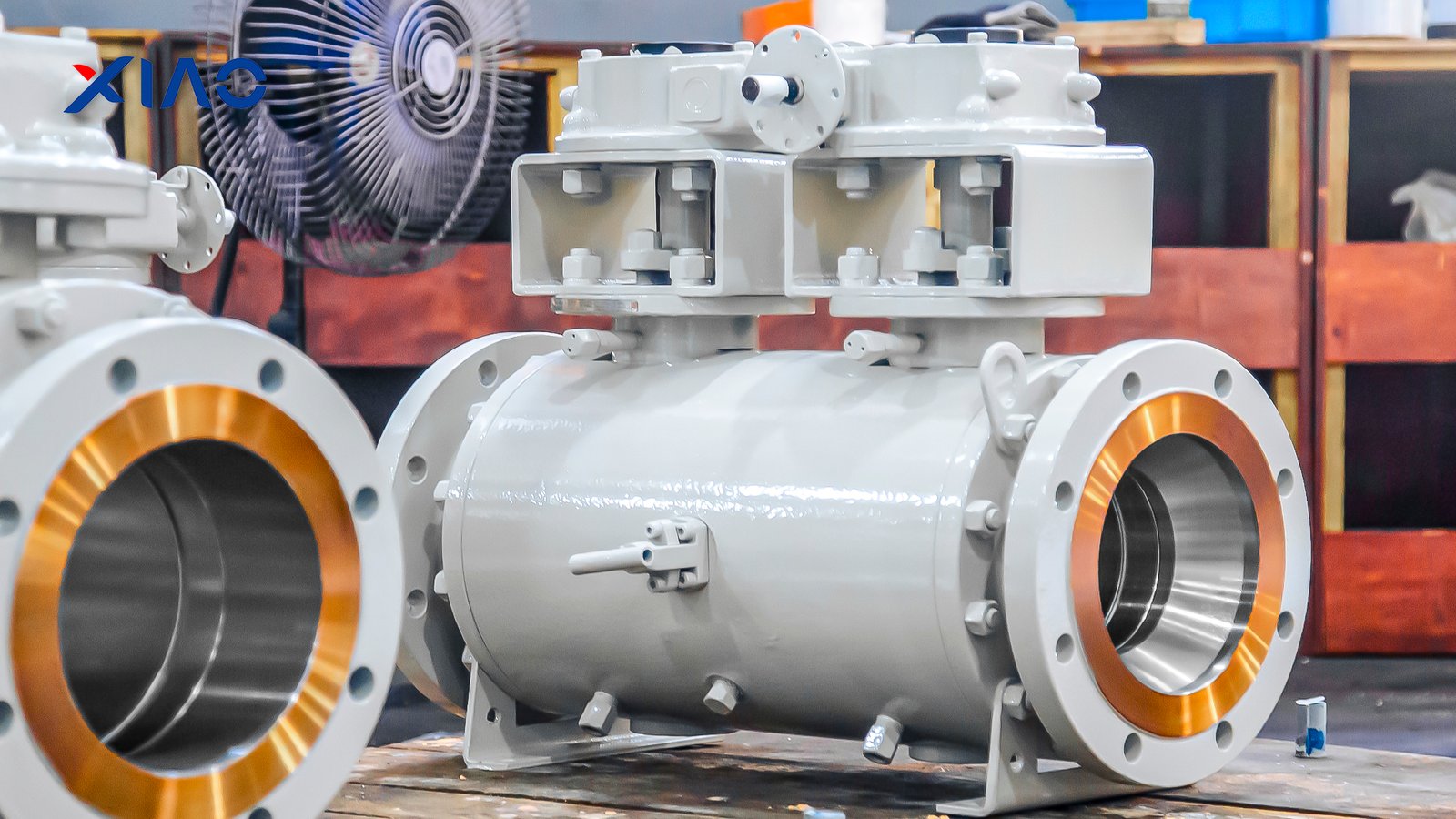

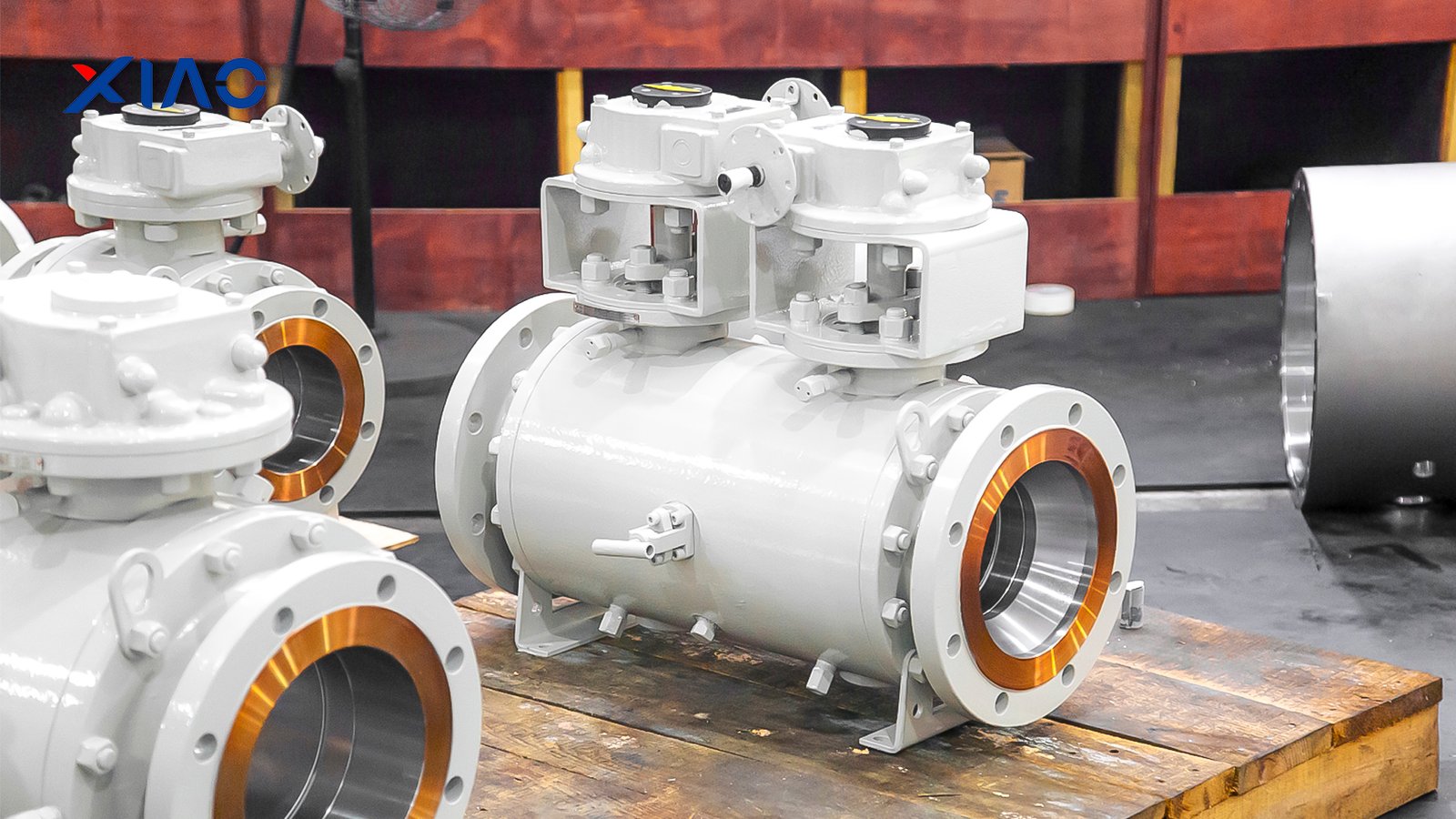

DBB Ball Valves – Double Block and Bleed Ball Valves for High-Integrity Isolation

Double Block and Bleed (DBB) Ball Valves are critical components in modern industrial systems where positive isolation and enhanced safety are non-negotiable. Whether you’re operating in the oil & gas, petrochemical, power, marine, or processing industry, having reliable flow control solutions that prevent leaks, contamination, and safety risks is essential.

Our range of DBB ball valves is engineered to provide superior performance, robust sealing, and complete shut-off capabilities. Designed to meet international standards like API 6D, ASME B16.34, and ISO 14313, these valves are trusted worldwide for high-integrity operations.

What is a DBB Ball Valve?

A Double Block and Bleed Ball Valve is a specialized valve design that integrates two separate sealing mechanisms (blocks) and a bleed port in a single valve body or as two valves in series. This configuration allows operators to isolate the pipeline segment from both upstream and downstream pressure and safely release trapped fluid or gas via the bleed port.

This type of valve is widely used where:

- Safety is paramount

- Pipeline sections require maintenance or inspection

- Contaminant prevention is necessary

- Pressure verification or system testing is required

In contrast to standard ball valves, DBB valves provide redundant sealing, significantly reducing the chance of leakage or cross-contamination during critical operations.

Key Features of Our DBB Ball Valves

When choosing a DBB valve, performance, compliance, and reliability are non-negotiable. Here’s why our DBB ball valves are the preferred choice across industries:

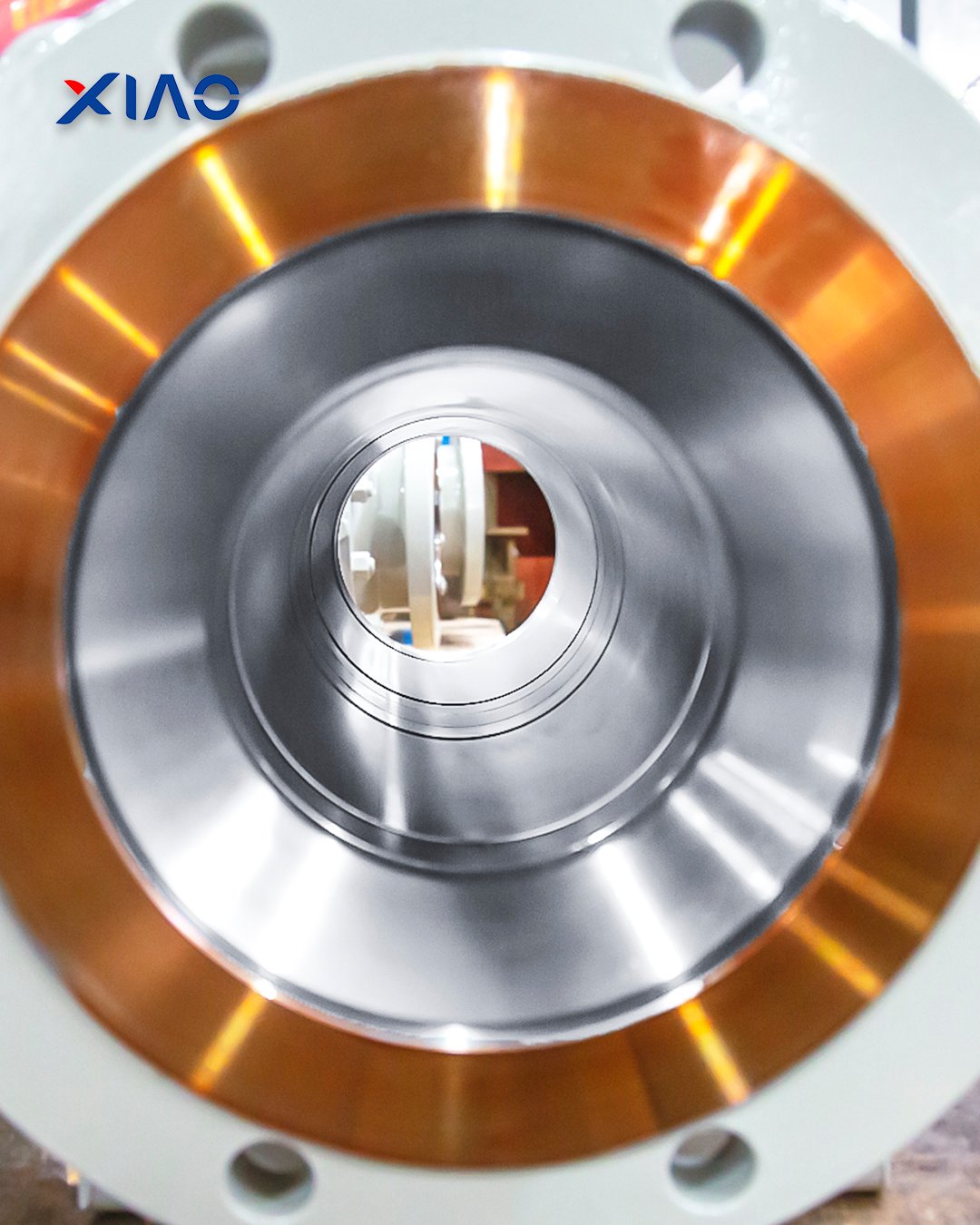

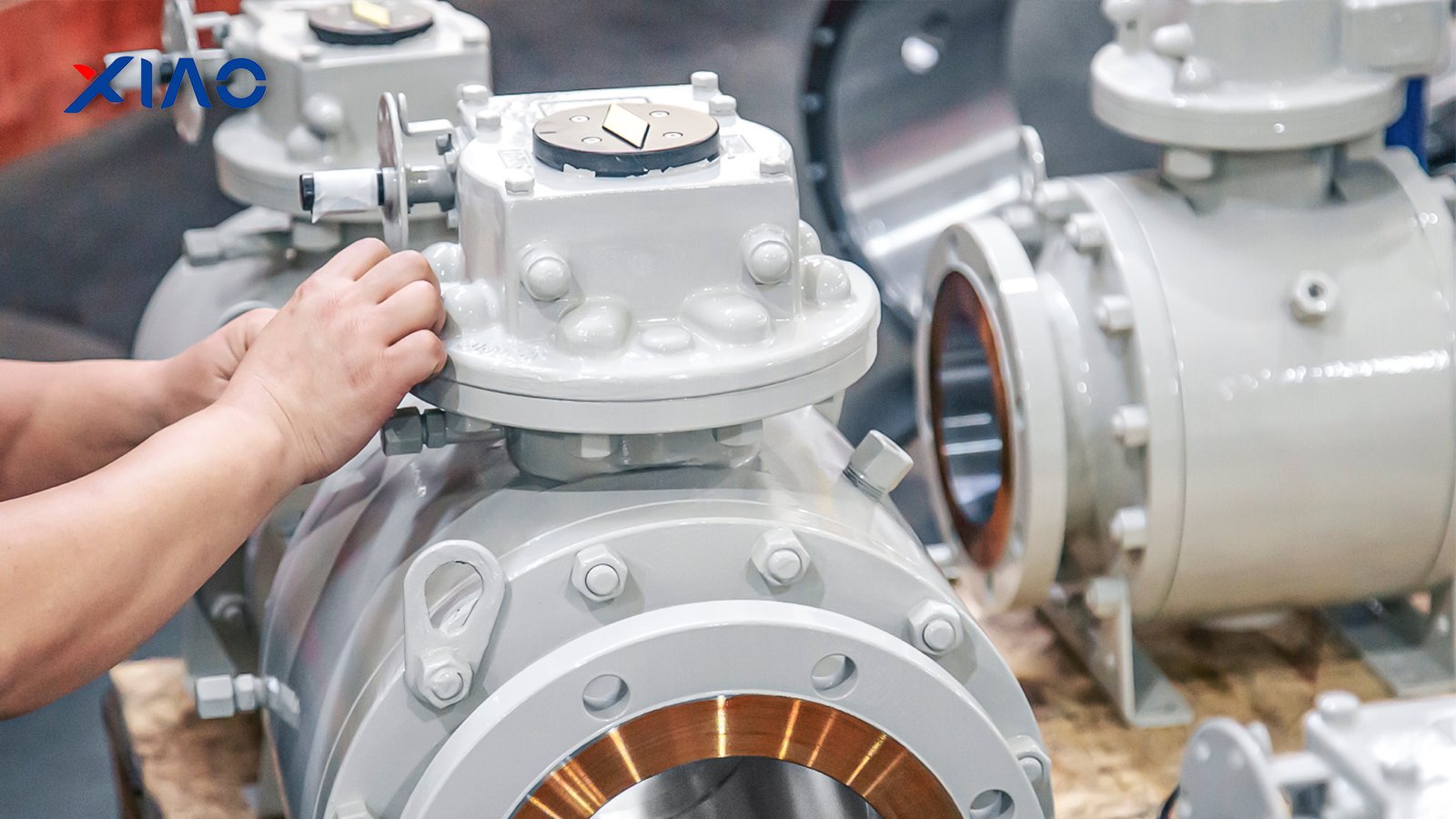

Dual Isolation (Double Block)

Our valves incorporate two independent seating surfaces within a single body. This ensures complete isolation from both ends of the pipeline, even if one seat fails.

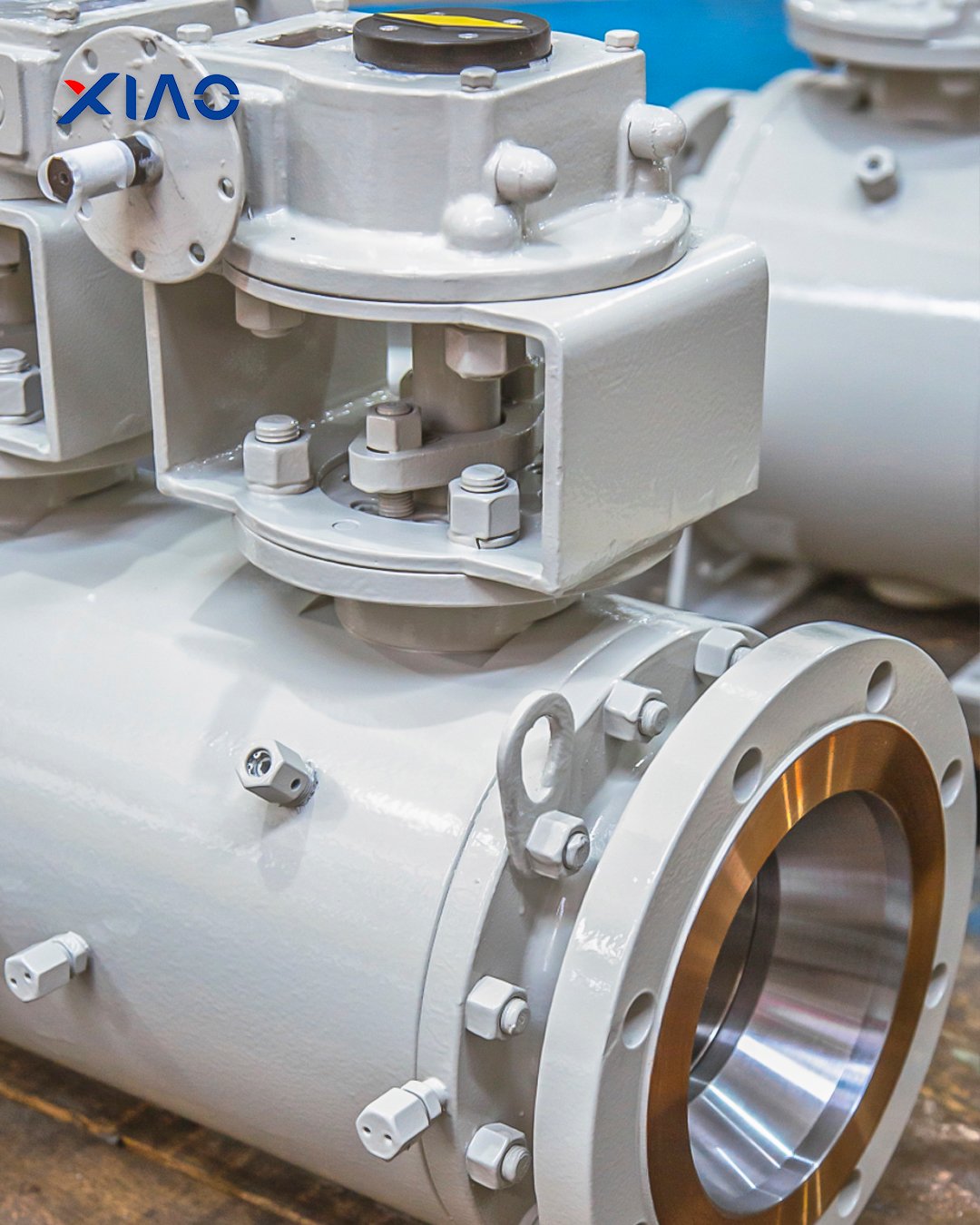

Bleed Function

An integrated bleed valve enables the release of trapped fluid or gas between the blocks, ensuring safety and enabling verification of seat integrity.

API & ISO Standards

All valves are manufactured and tested in compliance with API 6D, ASME B16.34, ISO 14313, and NACE MR0175 (for sour service).

Fire-Safe & Anti-Blowout Design

Fire-safe certification ensures the valve maintains integrity during high-temperature exposure, while anti-blowout stems enhance operational safety.

Custom Configurations

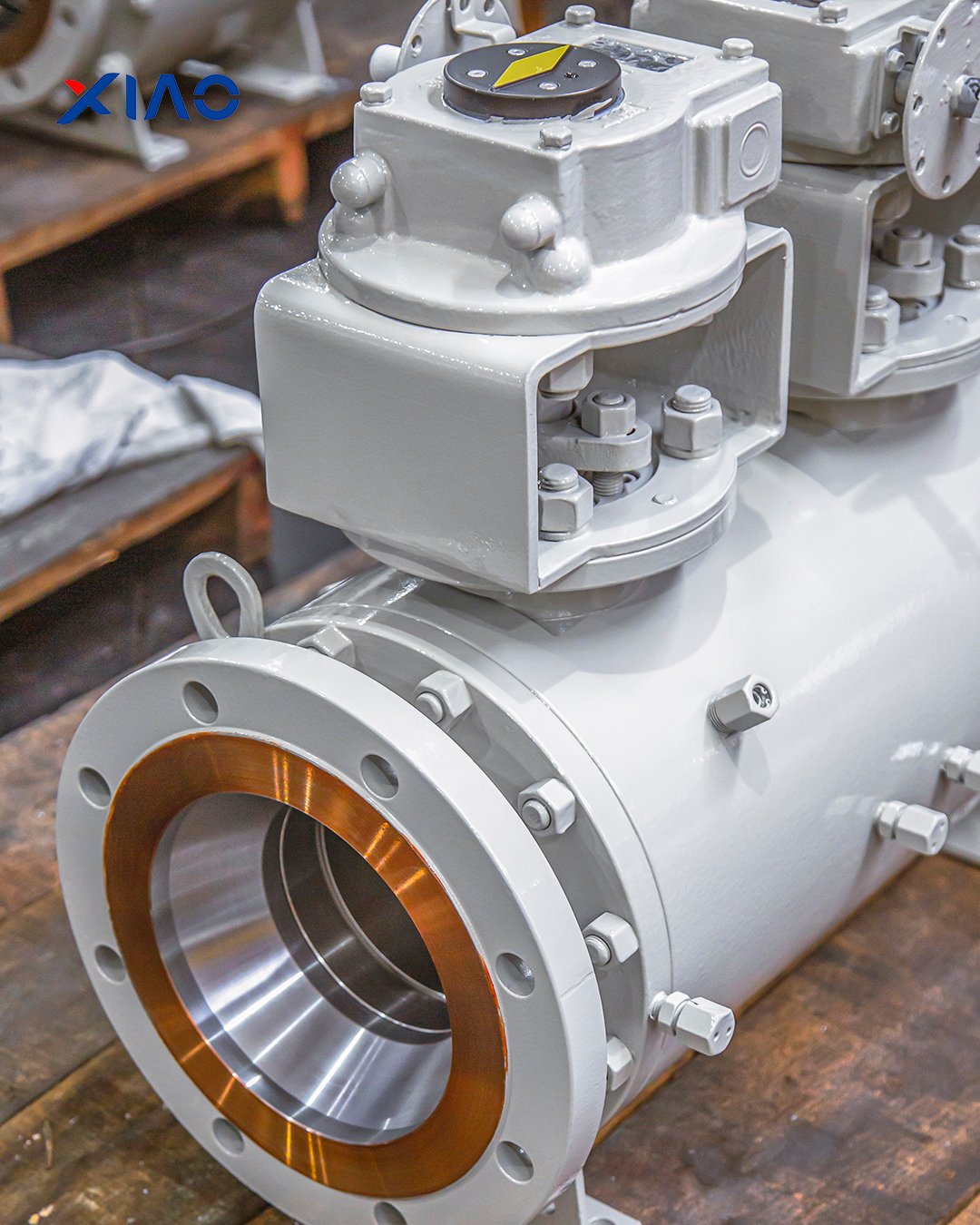

Available in soft or metal-seated options, full or reduced bore, floating or trunnion-mounted designs, and sizes from ½” up to 48”.

Corrosion & Erosion Resistance

Body materials include carbon steel, stainless steel, duplex, and other special alloys to suit harsh environments, including subsea and offshore.

Common Applications of DBB Ball Valves

DBB valves are used when zero-leakage and verified isolation are required. They are especially critical in environments where product purity, pressure control, and human safety are at risk. Here are some common applications:

Oil & Gas Industry

Used for pipeline isolation, manifold systems, and metering skids, especially where high-pressure and hydrocarbon control are required.

Petrochemical & Refining

Provides safe isolation during maintenance of process equipment, reducing the risk of cross-contamination or chemical leaks.

Power Generation

Ensures secure operation in high-pressure steam and cooling water systems, especially in nuclear and thermal power plants.

Marine & Offshore Platforms

Used for drilling rigs, FPSOs, and subsea operations where reliability and compact design are critical.

Chemical Processing

Prevents media mixing and allows for quick line checks, ideal for systems handling aggressive or hazardous chemicals.

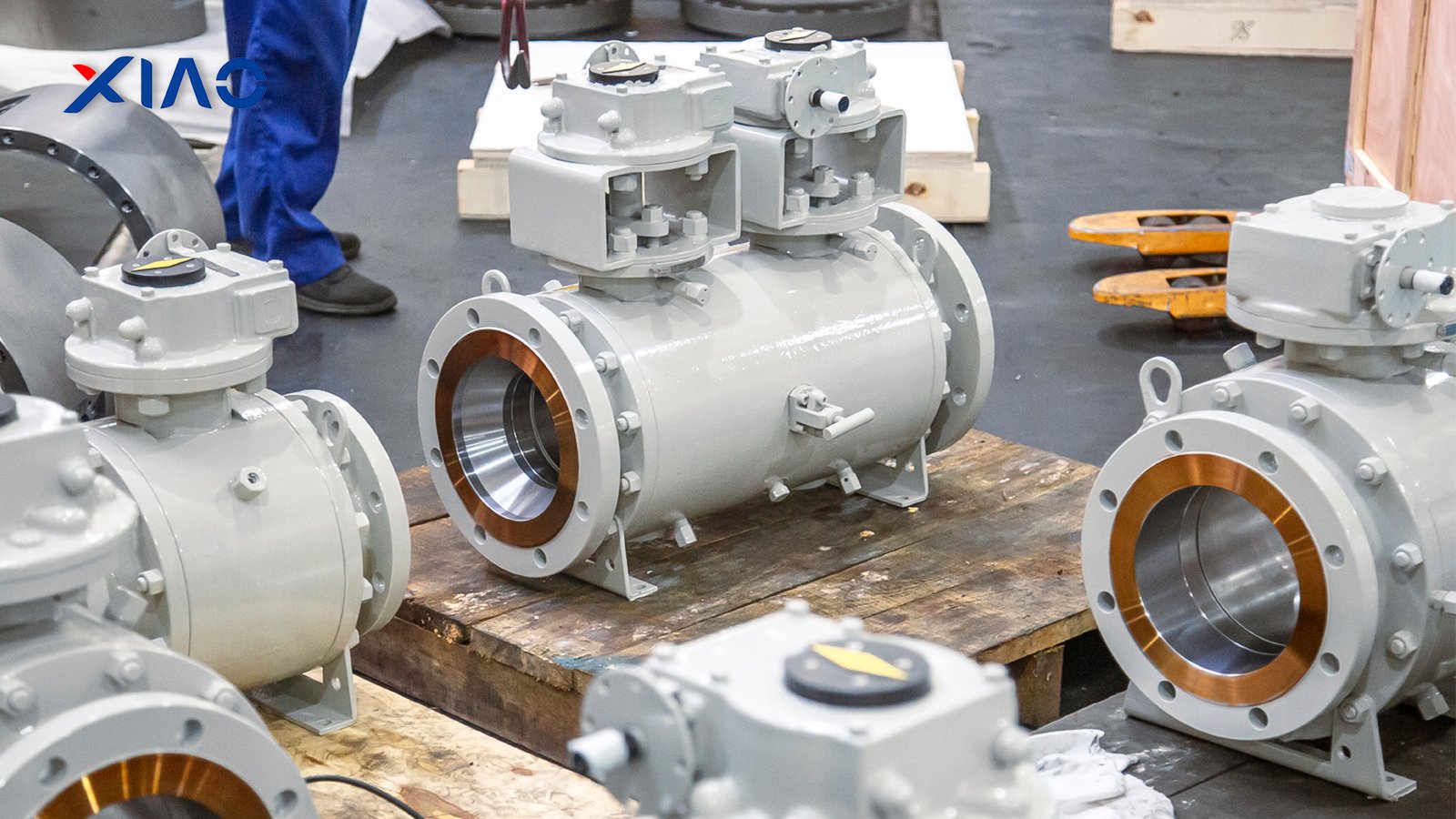

DBB Ball Valve Types We Offer

We offer a wide range of DBB ball valve configurations to match your application:

Trunnion-Mounted DBB Ball Valve

Perfect for high-pressure applications. Offers excellent torque control and seat performance in large-bore pipelines.

Floating DBB Ball Valve

Used for low to medium-pressure applications. Cost-effective and ideal for smaller systems requiring double isolation.

Single Body DBB Valve

Compact and lightweight. Integrates all functions into a single forged body, reducing the number of leak paths and weight on skids.

Twin Ball DBB Valve with Needle Bleed

Combines two balls with a needle valve for bleeding, commonly used in instrumentation systems and pressure measurement lines.

Forged & Cast DBB Valves

Choose from forged steel for compact, high-strength designs or cast body for large-scale operations.

Advantages of Using DBB Ball Valves

Choosing the right DBB valve is not just about meeting regulations—it’s about protecting systems, people, and the environment. Here are the core benefits:

Maximum Safety

With redundant sealing and bleed verification, DBB valves minimize the risk of leaks and protect operators during maintenance or shutdown.

Simplified Maintenance

Single-valve DBB designs reduce the number of valves and connections, lowering installation and maintenance time.

Cost Efficiency

DBB valves help reduce downtime and the number of components needed in a system—leading to long-term operational savings.

Compact Design

Ideal for space-limited installations such as offshore platforms, skids, and FPSOs, where compactness without sacrificing safety is essential.

Environmental Compliance

Zero leakage means reduced emissions and a smaller carbon footprint—helping your business meet environmental targets and sustainability goals.

Why Choose Us for DBB Ball Valves?

We are a trusted name in industrial valve solutions, delivering engineered products that meet or exceed customer expectations in performance, durability, and compliance. When you choose our DBB ball valves, you get:

Global compliance with industry-leading certifications

Custom-engineered solutions for unique applications

Fast lead times and global delivery

Dedicated technical support for selection, installation, and after-sales service

How to Select the Right DBB Valve

Selecting the right DBB ball valve involves careful consideration of:

- Application pressure & temperature

- Media type (gas, oil, chemical, etc.)

- End connections (flanged, threaded, welded)

- Material compatibility

- Actuation needs (manual, pneumatic, electric)

Not sure what you need? Contact our valve engineers and we’ll help you choose the right configuration for your operation.