Cryogenic valves are very special tools that are made to work in places where the temperature is always very cold. These are not standard valves like the ones we use at home. These are used in places where the cold can be so extreme that other machines might stop working or break down. But these valves stay strong and keep working. That is why big companies in many industries use them to stay safe.

The word “cryogenic” means very, very cold. Some people say cryogenic cold starts at -40°F (-40°C), but these valves are often used in places where it is even colder than -320°F (-196°C). That’s much colder than the inside of your freezer or even colder than liquid nitrogen! These valves are made with strong materials to survive and work well in these icy conditions.

Where Cryogenic Valves Are Used

LNG Terminals and Cold Gas Plants

In the oil and gas industry, many jobs use cryogenic valves daily. Gases like nitrogen, methane, and helium are cleaned and cooled until they become liquids. Turning gas into liquid is vital because it takes up less space, making storing and moving to other places easier and safer.

Before the gas turns into a liquid, workers must remove things like water, carbon dioxide (CO2), and hydrogen sulfide (H2S). These things can damage the pipes and the valves. After cleaning, the gas is cooled down, and the cryogenic valves help control how the cold liquid moves. These valves stop leaks, maintain the pressure, and keep everything flowing smoothly.

Cryogenic Processing

Cryogenic processing is a special method that uses cold temperatures to improve things. After World War II, this method became more popular. 1966 Ed Busch showed how freezing metal tools could make them stronger and last longer. This is called cryogenic tempering. Tools treated this way could last two, three, or even four times longer than usual.

Factories use cryogenic valves to help with this freezing process. These valves help control the super-cold liquids that freeze metal tools and machine parts. The same kind of valves are also used in food freezing plants. Freezing food quickly helps it stay fresh for longer. It stops bacteria from growing and keeps ice crystals from damaging the food.

Medical companies also use cryogenic valves. They freeze things like vaccines, blood, and other health products. These products must stay very cold or they won’t work correctly. Cryogenic valves help keep these things frozen and safe during storage and transport.

Space and Rockets

Cryogenic valves are also super important for space programs. Rockets use very cold fuel, like liquid hydrogen and liquid oxygen. These are called cryogenic fuels because they stay liquid at freezing temperatures. This fuel helps rockets launch with a lot of power.

Cryogenic valves help move this cold fuel from the storage tanks to the rocket engines. These valves are built to stop leaks and ensure fuel flows at the right speed and time. Handling rocket fuel is very dangerous, so it’s essential to have safe valves. Cryogenic valves help make sure the launch goes smoothly and safely.

Different Types of Cryogenic Valves

There are many kinds of cryogenic valves. Each one is made to do a different job. Some valves are made to open and close the flow completely. Others are used to control how fast the liquid or gas moves. Some are small and used in tight places. Others are big and used in huge factories.

All cryogenic valves are made to stop leaks. Even a small leak can cause many problems when working with cold liquids or gases. These valves have strong seals and are made with materials that don’t crack or break easily. Picking the correct valve for the job is vital to keep the system safe and working.

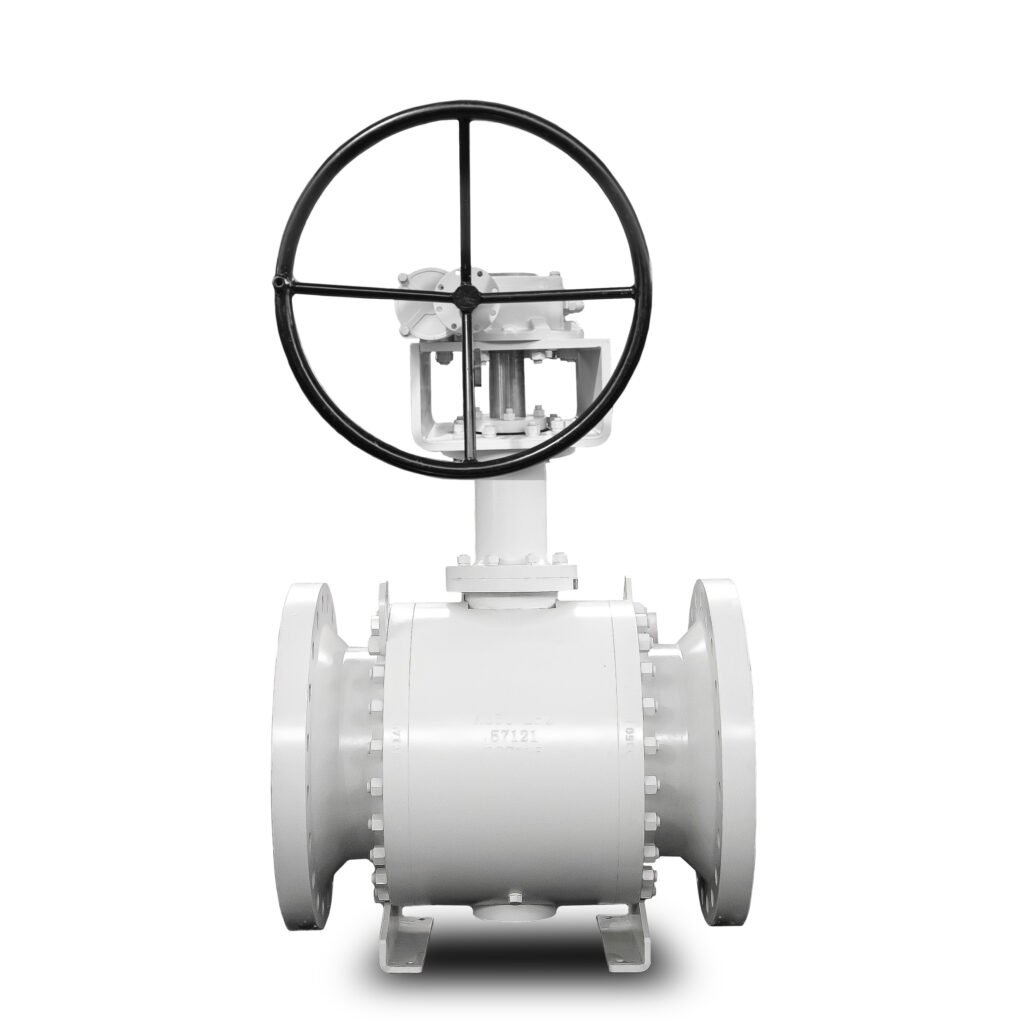

Cryogenic Ball Valves

Cryogenic ball valves are one of the most common and trusted cryogenic valves. They are used often because they can open and close the flow well. These valves often have two seals to stop any leaks from happening. Brands like L&T and AMPO Poyam are known for making good ball valves.

Inside the ball valve is a small space where a bit of the cold liquid can turn into gas if it warms up just a little. This helps stop the valve from freezing inside. The part of the valve called the stem stays close to room temperature, which allows the valve to last longer.

Ball valves are strong, but they can wear out if they are opened and closed too often. The ball inside and the seals can get damaged with too much use. That’s why these valves are best used where the flow stays on most of the time and the valve is not open and closed all day.

Gate Valves

Gate valves are another kind of cryogenic valve. These valves are also used to control icy liquids. Gate valves usually have a special hard coating called Stellite. This coating is used on the seat and disc parts of the valve. It helps stop the valve from wearing out because cryogenic liquids have slight slipperiness. The Stellite coating keeps the valve strong and helps it last longer. Gate valves are perfect for systems where you must open or close the liquid flow completely.

Standards: Cryogenic Valves

Cryogenic valves must follow special rules to ensure they are safe and made the right way. These rules are called standards. Standards help people build valves similarly, so they work safely worldwide. Some companies add even more regulations to make sure everything is extra safe.

MSS SP-134

MSS SP-134 is a cryogenic valve standard mainly used in North America. This rule explains how to pick good materials, build the valve safely, and test it before using it.

- Materials: The parts of the valve that touch the cold liquids need to be very strong and not break in the cold. Tables like ASME B31.3 Table A1 and ASME B16.34 Table 1 list the right materials and parts. If the valve has a pipe extension, it must be seamless, meaning it has no weld lines. Seamless parts are safer and stronger.

- Fabrication: The people who weld the valves must be trained well. All welds must follow the rules in ASME B16.34 Section 2.1.6. Each weld must be checked carefully to ensure it is safe and won’t crack.

- When the temperature changes even a little, it can make a lot of pressure inside the valve. That’s why many cryogenic valves have small vents to let out the extra pressure and keep the whole system safe.

- Production Pressure Testing: The valves must be cleaned to remove dirt or oil before testing. Then the valves are tested following the customer’s order and the ASME B16.34 rules. After testing, the valves must be dried carefully so no water is left inside.

BS 6364

BS 6364 is a British standard. It explains how to build and test cryogenic valves in the UK and other places that follow British rules.

All valves must have long bonnets or necks. This helps keep the valve parts warm enough to work correctly. The valve stem must be tilted at least 45° up from the side-to-side line for liquid service. The stem must be at or above the side-to-side line for gas service. The stem can be tilted 15° or more for cold box service.

Valves must have a way to let out extra pressure. Cryogenic systems can build up pressure when liquid turns into gas. This additional pressure must be controlled to prevent accidents.

Globe valves cannot have flat discs. They must use cone-shaped or tapered discs. This keeps things safe from sparks that could cause fires.

BS 6364 also explains how to test the first new valve design and all the valves made afterward.

ASME 16.34

ASME 16.34 is another essential standard. It tells how to make the valve parts, including the flanges, threads, and welded ends. It also covers:

- How to test the valve body to make sure it is strong

- How to check for leaks

- How to pick the right materials

- How to label and mark the valve parts

ISO 21011

ISO 21011 is an international standard. It is used all over the world. It tells how to build valves that work at normal and cold temperatures.

- Materials: Metal parts must follow ISO 21028-1 rules. Non-metal parts must follow ISO 21028-2. Non-metal parts must not break down from sunlight, aging, or bad weather. If the valve is used with acetylene, it cannot have more than 70% copper because that would be unsafe.

- Design: The valve must work safely from freezing temperatures up to 65°C. The walls of the valve must be thick enough to handle pressure. The valve stem must be long enough to keep the packing warm. There must be no small spaces inside the valve that could trap liquid. Trapped liquid could turn into gas and cause dangerous pressure build-up.

Other Standards

There are also other helpful standards for cryogenic valves. These include:

- ISO 5208: For pressure testing

- ISO 10434: For steel gate valves with bolted bonnets

- ISO 11114-1: For the safety of metal parts with gases

- ISO 11114-2: For the safety of non-metal parts with gases

- ISO 15761: For small steel valves used in oil and gas

- ISO 17292: For metal ball valves

- ISO 21010: For checking material compatibility for cryogenic use

- ISO 21028-1 and 21028-2: For testing how tough materials are at cold temperatures

- ISO 23208: For cleaning vessels used in cryogenic service

Testing Process of Cryogenic Valves

Cryogenic valves must undergo many tests to ensure they are safe and work properly. Each type of valve has its own tests, but some tests are always done no matter what type of valve it is.

- Shell Strength Test: This test checks if the valve’s body is strong enough. It is done using water or air. The pressure is 1.5 times higher than the standard system pressure to make sure the valve can handle stress.

- Shell and Seat Leak Test: This test checks if the valve leaks. The valve is tested at 1.1 times the normal pressure for air tests. The valve is tested at 1.3 times the normal pressure for water tests.

- Cryogenic Prototype and Production Test: These tests follow the rules of BS 6364. They check if the valve works properly at cold temperatures.

Recent Comments