A DBB NPT SW BW Flanged Ball Valve is essential in many industries. It enables managing the glide of liquids and gases, ensuring protection and efficiency. Double Block and Bleed Ball Valve include different connection types and NPT, SW, BW, and flanged ends. Each type serves a unique cause, depending on the device in which it is utilized. Knowing how the valves are used and how they are painted can help industries perform extra without difficulty and as they should.

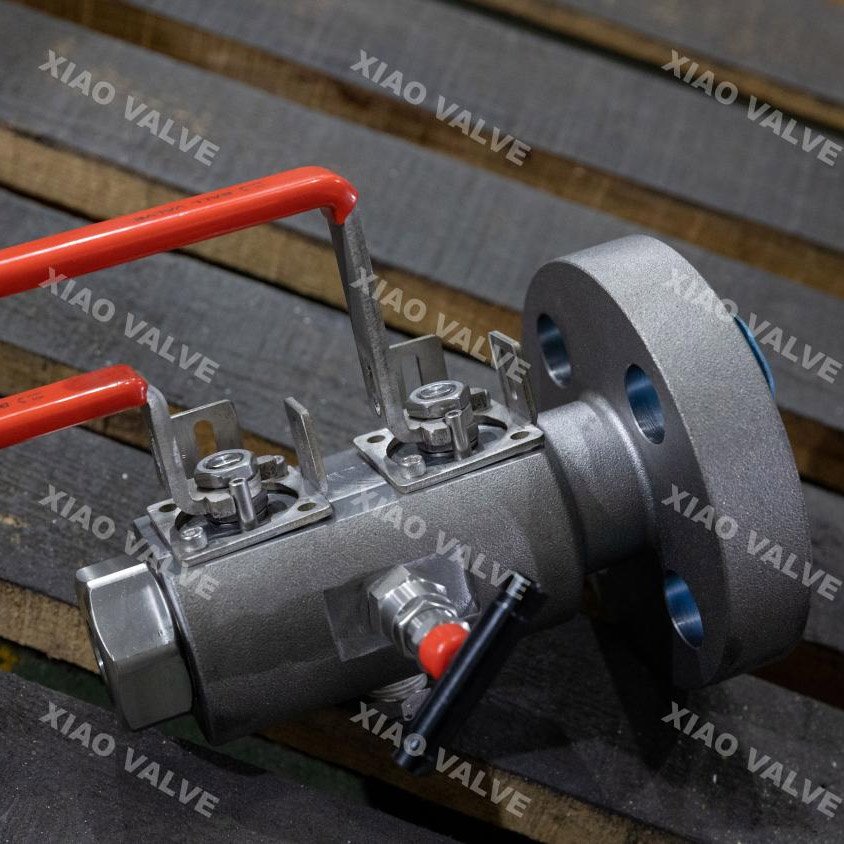

A DBB NPT SW BW Flanged Ball Valve is a special type with sealing mechanisms. It indeed prevents the float of liquid or gasoline, preventing leaks. It additionally has a bleed function that lets in the release of stress or drainage of fluid maximum of the two blocks. These industrial pipeline valves are utilized significantly in oil and gas, chemical processing, and water treatment industries. The specific connection sorts—NPT (National Pipe Thread), SW (Socket Weld), BW (Butt Weld), and flanged—decide how the valve attaches to the pipeline. Choosing the right connection type is crucial for ensuring the valve works well.

One of the High-Pressure DBB NPT SW BW Flanged Ball Valve’ most critical benefits is their ability to offer a smooth close-off. Two sealing surfaces prevent fluid from passing through simultaneously while the valve is closed, lowering the threat of leaks and growing protection.

Another advantage is their capability to launch stress. The bleed function lets any trapped fluid or fuel go, reducing pressure. This is crucial in high-strain systems where extra pressure can cause harm or accidents.

High-strain ball valves additionally help preserve the area. Instead of using several valves to gather a double block and bleed feature, a single flanged Connection Ball Valve can do the activity. This reduces the range of connections and minimizes the threat of leakage.

These valves are also exceptionally long-lasting. They are made from sturdy substances that resist corrosion and are placed on. This makes them a value-powerful choice because they require a bargain less protection and feature an extended lifespan.

Another key gain is easy preservation. Since corrosion-resistant ball valves are designed to be quickly mounted and eliminated, they permit brief inspections and renovations. This reduces downtime and enables industries to maintain smooth operations.

DBB NPT SW BW Flanged Ball Valves are used in lots of industries because they assist in controlling fluid drift and save you from leaks. In the oil and gas industry, these valves isolate pipeline sections to prevent contamination and make protection more secure. Refineries and petrochemical flora use them to avoid exceptional fluids from mixing.

In the chemical industry, socket weld ball valves care for dangerous fluids, lowering the danger of spills or leaks. The water remedy industry relies on those valves to manipulate strain and isolate parts of the system at some stage in maintenance. Power plants, aviation fueling systems, and even marine industries also use those Butt Weld Valve Applications for protection and efficiency. They play a key position in retaining systems running smoothly.

Each connection type has a different manner of attaching to a pipeline. NPT (National Pipe Thread) connections have threaded ends, making them clean to install and remove. These are, by and large, utilized in low-strain systems. SW (Socket Weld) connections contain welding the pipe into a socket, creating a sturdy leak-evidence joint—this type is acceptable for high-stress and high-temperature environments.

BW (Butt Weld) connections require welding the pipe ends immediately, forming an easy and seamless connection. This type is used in crucial packages where a sturdy joint is needed. Flanged connections use bolts to connect the valve to the pipeline. This makes them easy to install and do away with, which is why they’re regularly used in massive pipelines and heavy-duty industries. Choosing the proper connection depends on the gadget’s needs and running conditions.

Picking the correct connection type is critical for the valve to function well. If a machine has low strain and needs clean installation, NPT is an excellent choice. SW or BW is higher if the device requires a sturdy and permanent joint. SW is incredible for mild strain and temperature, while BW is right for intense conditions. Flanged connections are an excellent option if the device wishes frequent maintenance because they can be easily removed and replaced. Understanding the machine’s running conditions and preservation needs will help select the high-quality Oil and Gas Isolation Valve.

Finding a relied-on dealer is essential when shopping for DBB ball valves. ‘Xiaovalve Company’ is one of the best companies in China for DBB NPT SW BW flanged ball valves. They offer terrific valves that might be long-lasting and dependable. Their products meet global requirements, ensuring safety and performance in distinct industries. With plenty of connections, Xiaovalve Company offers solutions for oil and gas, chemical and water remedies, and other industries. Choosing a reputable dealer like Xiaovalve Company ensures you get the pleasant DBB ball valves you desire.