Description

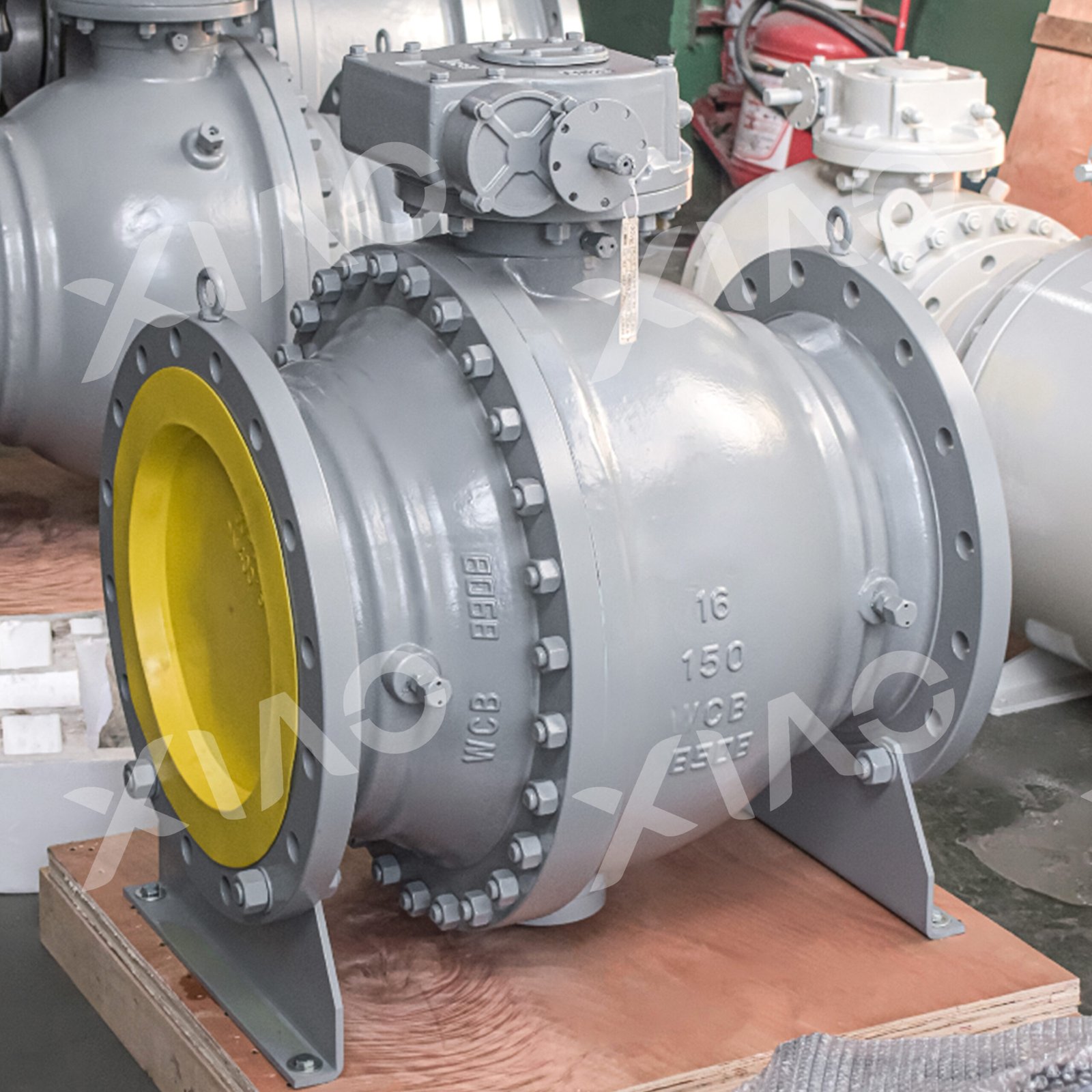

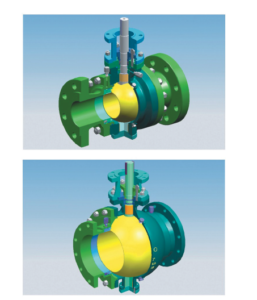

Cast Trunnion Ball Valve Series

Mould Example:CTQ347H-150LB ~ CTQ347H-600LB

Material Options

| WCB | CF8M |

| Class 150~300LB | Class 150~600LB |

| -29℃ ~ 425℃ | -196℃ ~ 450℃ |

Technical Specs

| Parameters | specification |

| Size | DN50~DN1200 (2″~48″) |

| Connection | Flange (RF/RTJ) |

| Sealing | Metal Seat/PTFE |

| Certification | API 6D/CE-PED |

Hot Applications

Oil & Gas Stations: 10,000+ units/year for pipeline hubs

Chemical Plants: WCB+PTFE combo cuts cost by 25%

Pharma Grade: 316L+EP finish, FDA/3-A compliant

| Feature |

|---|

| Size: 2″ – 40″ |

| Class: 150~900Lb |

| Three & Two Pieces Cast Steel Body |

| Trunnion Mounted Ball, Full & Reduced Bore |

| Anti-static Device |

| Blow-out Proof Stem |

| Fire Safe Design |

| Emergency Sealant Injector |

| Vent valve, drain valve |

| Lifting lugs and supporting feet (8″ & larger) |

| Specification | Standard |

|---|---|

| Design | ASME B16.34 / API 6D |

| Face to Face | ASME B16.10 |

| End Flange | ASME B16.5 |

| B/W End | ASME B16.25 |

| Test | API 598 |

| Fire Safe Test | API 607 / API 6FA |

| Special | NACE MR-01-75 |

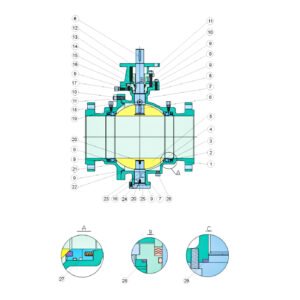

The illustration below showcases a detailed cross-sectional view of a valve, likely a ball valve or similar flow control device. Key components are numbered to help identify each part of the assembly.

Central Ball Valve: The large, yellow circular component represents the ball, which controls the flow through the valve. The hole in the ball allows for flow when aligned with the pipe.

Detailed Views: The three insets (labeled A, B, and C) provide close-ups of specific areas of the valve:

View A: Highlights the ball area, including the seals and other critical parts.

View B: Offers a closer look at the sealing mechanism or mechanical components involved in valve operation.

View C: Focuses on the connection points and sealing area near the valve stem.

The use of color coding in the diagram helps to easily differentiate between various parts and materials, such as the valve body, stem, seals, and other components crucial to the operation of the valve.

Materials List for Valve Components and Parts

| No. | Part | Material |

| 1 | Body | ASTM A216-WCB, A352-LCB, A351-CF8, CF8M, CF3, CF3M, Duplex |

| 2 | Seat Spring | Inconel X-7505, S304, SS316 |

| 3 | Seat Ring | ASTM A105+ENP, ASTM A182-F304, F316, F316L, F51,F6A |

| 4 | Seat | PTFE, RPTFE, PEEK, PPL |

| 5 | Ball | ASTM A105+ENP, ASTM A182-F304, F316, F316L, F304L,F6A |

| 6 | Key | 1045, A182-F304, F316, F316L, F304L |

| 7 | Sliding Bearing | Stainless Steel+PTFE, SS316+PTFE |

| 8 | Thrust Washer | PTFE |

| 9 | O-ring | NBR, Viton |

| 10 | Stud | ASTM 193-B7, B7M, B8, B8M |

| 11 | Nut | ASTM 194-2H, 2HM, 8, 8M |

| 12 | Yoke | A216-WCB |

| 13 | Gland Flange | A216-WCB, A351-CF8 |

| 14 | Stem | A105+ENP, A182-F6, F304, F316, F316L, F304L, 17-4PH, F51 |

| 15 | Packing | PTFE, Graphite |

| 16 | Screw | ASTM A193-B7, B8 |

| 17 | Stem Injection | 1020+ZN, A182-F304, F316, F316L, F316L |

| 18 | Seat Injection | 1020+ZN, A182-F304, F316, F316L, F316L |

| 19 | Vent Valve | 1020+ZN, A182-F304, F316, F316L |

| 20 | Antistatic Spring | Stainless Steel, SS316 |

| 21 | Bonnet | A216-WCB, A352-LCB, A351-CF8, CF8M, CF3, CF3M, Duplex |

| 22 | Body Gasket | PTFE, SS304+Graphite, SS316+Graphite |

| 23 | Trunnion | A105+ENP, A182-F304, F316, F316L, F304L, F51,F6A,17-4PH |

| 24 | Bottom Cover | A105+ENP, A182-F304, F316, F316L, F304L, F51 |

| 25 | Lower Gasket | PTFE |

| 26 | Drain Valve | 1020+ZN, A182-F304, F316, F316L |

| 27 | Seat Sealing | Graphite, SS304+Graphite |

| 28 | Gland Gasket | SS304+Graphite |

| 29 | Bottom Cover Gasket | SS304+Graphite |