Description

Materials and Min Temperature Ratings

| Forged Material | Min Temp | Cast Material | Min Temp |

| ASTM A182 F316 / F304 | –254°C | ASTM A351 CF8M / CF3M | –254°C |

| ASTM A350 LF3 | –101°C | ASTM A352 LC3 | –101°C |

| ASTM A350 LF2 | –46°C | ASTM A352 LCB / LCC | –46°C |

Test & Quality Control

| Test Name | Conditions |

| Initial Proving Test | 1.1 × MDP @ Room Temperature, Helium |

| Torque Cycle Test | 20 open-close cycles |

| Seat Closure Leak Test | 1.1 × MDP @ –196°C, Helium |

| Shell Leak Test | 15 minutes @ –196°C, Helium |

| Restoration Test | Post cryo retesting at Room Temp |

✔ Conducted according to BS 6364, ISO 28921, and API 598

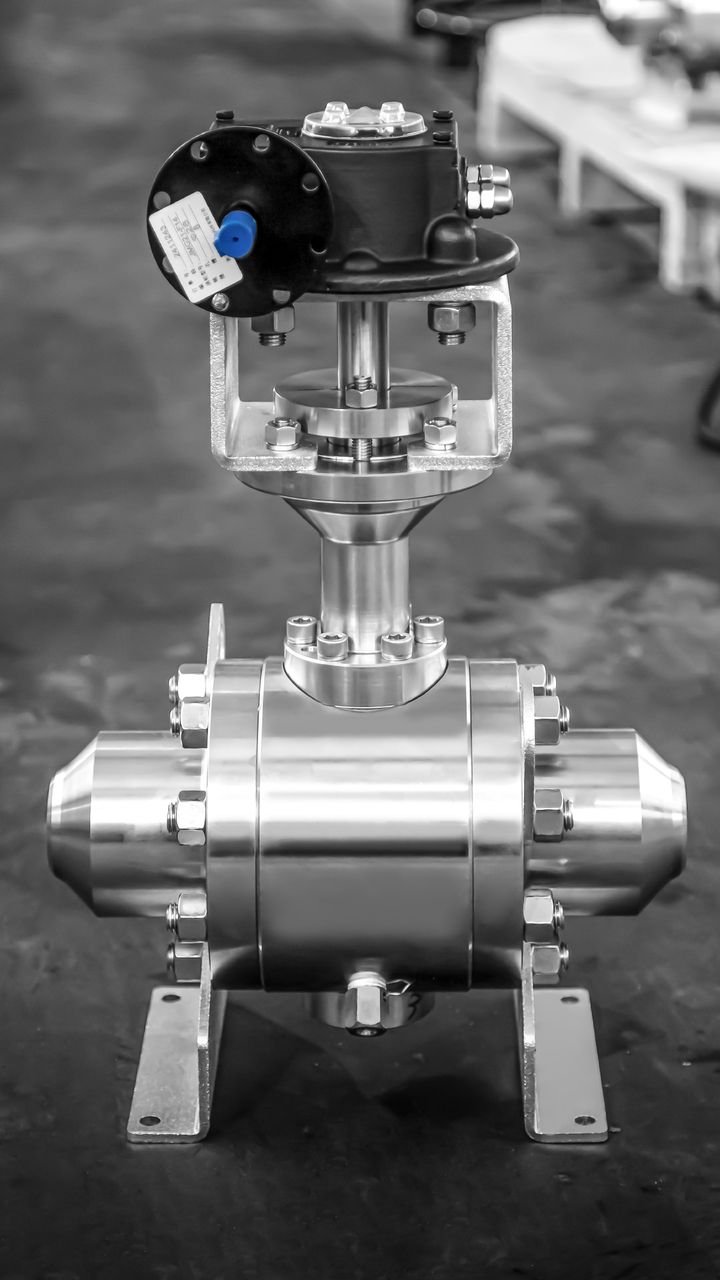

Construction Features – Ball & DBB Valves

- Extended Bonnet:

Positions gland packing away from cryogenic zone

Cavity Pressure Relief Options:

- Upstream port relief hole (unidirectional)

- Relief valve fitting (bidirectional)

- Self-relieving seat

Locking Devices: Padlock system for both manual and gear-operated valves

Actuation Options: Electric, pneumatic, hydraulic

- Seat Options:

- Soft Seat for –196°C

- Metal Seat for up to 850°C

- Soft Seat for –196°C

Specifications – Ball Valves

| Feature | Details |

| Valve Size | 1/2” to 14” (Top entry & 3-piece) |

| Pressure Rating | ASME 150–2500 |

| Temp Rating | –196°C |

| End Connections | Butt Weld, Flanged, SW, Threaded |

| Design | Floating / Trunnion, DBB |

| Standards | ASME B16.10, B16.5, B16.25, B16.11 |

| Test Standards | BS 6364, API 598, ISO 28921 |

| Wall Thickness | ASME B16.34 |

Materials of Construction – Ball Valve

| Component | Material |

| Body, Bonnet, Ball | ASTM A351 CF8M |

| Stem | ASTM A276-316 |

| Seat | PCTFE |

| Spring | Inconel X-750 |

| Gasket | Graphite + SS316 |

| Packing | Graphite |

| Bolts/Nuts | ASTM A320-B8 / A194-8 |