Description

Tech Specs

| Parameters | English |

| Pressure rating | Class150~600LB |

| Diameter range | DN50~DN800 (2″~32″) |

| Valve body material | WCB/CF8/CF8M |

| Seal combination | Metal+Graphite/PTFE |

| Applicable temperature | -196℃~450℃ |

Industry Pain Points

Oilfield Maintenance: 90% downtime reduction in desert pipelines

Chemical Corrosion: 3x lifespan with CF8M + tungsten coating

City Gas Safety: DBB prevents leakage, EN 331 certified

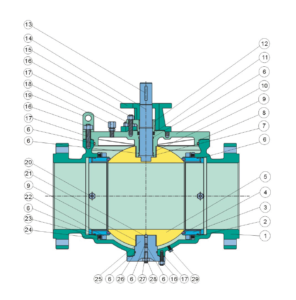

Trunnion-Mounted Ball Valve Cross-Section Diagram

This sectional diagram illustrates a trunnion-mounted ball valve, widely used in high-pressure pipeline applications. The design features a split body, monolithic cast construction, and a floating or trunnion-supported ball, allowing for both full and reduced bore configurations. Key features include:

- Blowout-proof stem for operational safety

- Anti-static device to prevent spark generation

- Fire-safe design with certified sealing systems

- Emergency sealant injection ports for critical shutoff

- PTFE/Graphite packing and O-ring seals to ensure leak-tight operation

Each labeled component (1–29) corresponds to a specific part listed in the material specifications table, supporting the valve’s durability, pressure integrity, and maintainability.

| Feature | Description |

|---|---|

| Size | 2″ – 24″ |

| Class | 150 – 1500Lb |

| Body Type | The Monolithic Cast Steel Body |

| Ball Type | Floating & Trunnion Mounted Ball, Full & Reduced Bore |

| Device | Anti-static Device |

| Stem | Blow-out Proof Stem |

| Design | Fire Safe Design |

| Sealant | Emergency Sealant Injector |

| Specification | Standard |

|---|---|

| Design | ASME B16.34 / API 6D |

| Face to Face | ASME B16.10 |

| End Flange | ASME B16.5 |

| BW End | ASME B16.25 |

| Test | API 598 |

| Fire Safe Test | API 607 / API 6FA |

| Special | NACE MR-01-75 |

| No. | Part | Material |

|---|---|---|

| 1 | Body | A216-WCB, A352-LCB, A351-CF8, CF8M, CF3, CF3M, Duplex |

| 2 | Seat Spring | Inconel X-7505, SS304, SS316 |

| 3 | Seat Ring | ASTM A105+ENP, ASTM A182-F304, F316, F316L, F6, F51 |

| 4 | Seat | PTFE, RPTFE, PEEK, PPL |

| 5 | Ball | ASTM A105+ENP, ASTM A182-F6, F304, F316, F316L, F51 |

| 6 | O-ring | NBR, Viton |

| 7 | Thrust Washer | PTFE |

| 8 | Body Gasket | Stainless Steel+PTFE, SS316+PTFE |

| 9 | Sliding Bearing | PTFE, SS304+Graphite, SS316+Graphite |

| 10 | Bonnet | A216-WCB, A352-LCB, A351-CF8, CF8M, CF3, CF3M, Duplex |