Industrial processes often require equipment that ensures safety, efficiency, and reliability. Among the various valves available, the DBB NPT SW BW flanged ball valve stands out for its particular design and flexible functionality. These double-block and bleach valves are essential for controlling the flow of liquids or gases in pipelines, making them crucial in oil and gas, petrochemicals, and power generation.

We can explain the DBB NPT SW BW flanged ball valve in detail. You’ll explore what it is, how it works, its connection types, its use, and why it’s so desired in your operations.

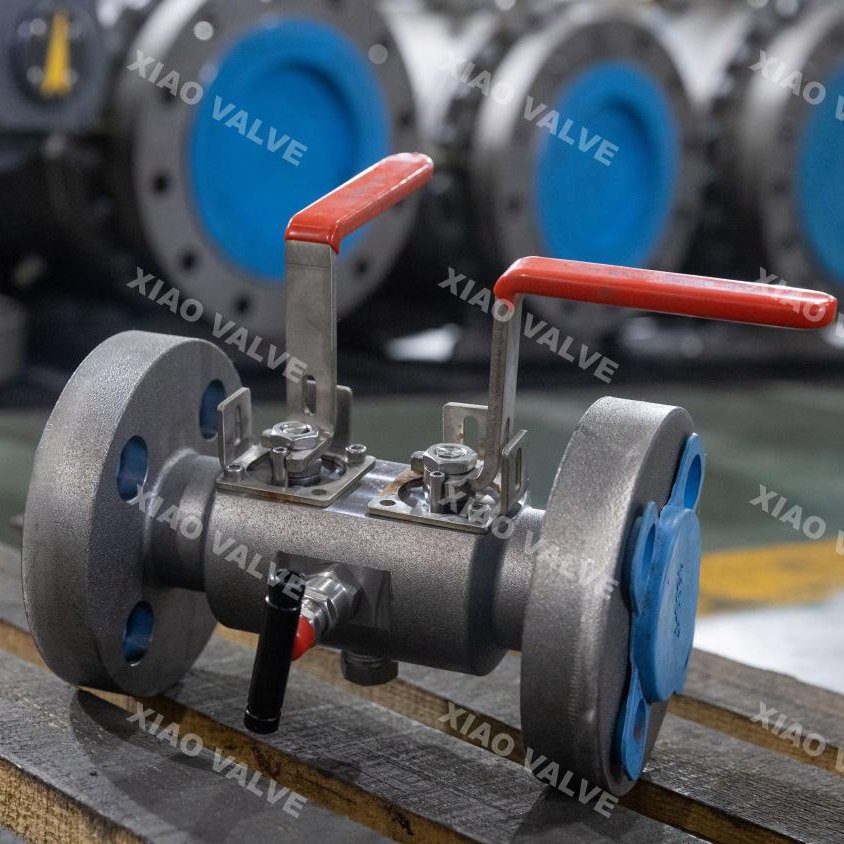

A DBB NPT SW BW flanged ball valve combines advanced features into one device. The term “DBB” stands for Double Block and Bleed. In this approach, the flanged Connection Ball Valve can shut off and go with the flow on both sides of the valve, permitting any trapped strain to be effectively released through a bleed mechanism. This design ensures better safety and performance.

The additional abbreviations describe the relationship types. NPT is National Pipe Thread, a threaded connection generally used in North America. SW refers to a Socket Weld, a connection in which the pipe suits into the valve and is welded for a leak-evidence seal. BW stands for Butt Weld, a welding approach wherein the valve and pipe are joined quit-to-give up. Flanged refers to bolted flange connections, making setup and removal simpler.

These NPT Threaded Ball Valves are designed with a ball-fashioned closure element that rotates to open or near the glide. Their sturdy production and specific engineering make them appropriate for high-pressure and excessive-temperature programs.

The working of a DBB ball valve revolves around its double block and bleed mechanism. When the valve is in the closed function, it blocks the fluid or gas flow from both ends. This is finished using unbiased sealing surfaces, ensuring there may be no leakage from either facet.

The socket Weld Ball Valve also has a bleed port between the block seals. Once the glide is blocked, any pressure trapped inside the center section may be thoroughly vented through this bleed port. This mechanism prevents stress buildup, ensuring safety during protection or inspection.

The ball within the valve is managed using a deal with or actuator. A sector turn of the car switches the valve between open and closed positions. This simple yet effective layout reduces downtime and complements operational efficiency. The DBB function is especially beneficial in systems where absolute isolation and dealing with hazardous substances are required.

This valve comes with exclusive connection options to suit diverse piping structures. Let’s recognize those connection types:

NPT (National Pipe Thread): NPT connections are threaded, making them clean to put in and dispose of. They are usually used in low-strain systems and for smaller pipelines.

SW (Socket Weld): With socket weld connections, the pipe is welded into a socket inside the valve frame. This creates a leak-proof seal and is suitable for excessive-strain applications.

BW (Butt Weld): Butt Weld Ball Valve connections require the valve and pipe to be welded collectively at their ends. This guarantees an easy and continuous pipeline, lowering turbulence and minimizing the probability of leakage. It is ideal for excessive-temperature and high-strain environments.

Flanged: Flanged connections contain bolted flanges, making setup, inspection, and elimination easy. They are desired for structures that require common preservation.

Each connection kind has its advantages and is selected primarily based on the unique necessities of the pipeline system.

DBB ball valves are exceptionally versatile and have applications in several industries. They are essential within the oil and gas enterprise, where they are necessary for keeping sections of pipelines separate and ensuring protection during protection or emergencies.

Industrial Ball Valve Solutions control unsafe fluids in the petrochemical region while stopping leaks. Power-era centers depend on valves to handle steam, gas, or high-stress media. They are also utilized in water treatment plants to make particular green drift management and isolation.

High-pressure ball valves are necessary for systems requiring sterile and leak-proof operations in the pharmaceutical enterprise. Their capacity to provide double isolation and a bleed mechanism makes them a pass-to preference for crucial tactics.

While these types of connections are used to join valves to pipes, each kind has specific characteristics. NPT connections are threaded, making them clean to bring together; however, they can also require sealants to prevent leaks. They are best for low-pressure systems.

Socket welds involve turning the pipe into a socket and welding it. This creates a strong leak-evidence connection suitable for better pressures. Butt welds join the valve and pipe stop-to-stop, forming a seamless joint. This reduces turbulence and is best for systems needing high integrity.

Flanged connections use bolts to stabilize the valve and the pipe. They are less complicated to install and preserve but might not be as leak-evidence as welded connections. The preference depends on strain, temperature, upkeep needs, and price concerns.

When sourcing DBB ball valves, locating a trusted dealer is critical. Xiaovalve Company is one of the leading providers of DBB NPT SW BW flanged ball valves in China. Xiaovalve manufactures valves using top-class materials and advanced technology. Every valve undergoes rigorous trying out to meet global standards.

We provide various options, including connection kinds, sizes, and strain rankings, to meet numerous business desires. With years of revel in the enterprise, Xiaovalve has constructed a reputation for turning in reliable and durable merchandise. Despite supplying top-notch, high-quality, Xiaovalve ensures aggressive pricing, providing you with a quality price for your funding.

Our team offers complete assistance, from product choice to after-income providers, to ensure your satisfaction. By deciding on Xiaovalve, you’re investing in products that guarantee protection, performance, and long-term performance.