In the oil and gas industry, security and reliability come first. Pipelines, refineries and processing plants handle dangerous fluids under high pressure. To protect operations, industries use advanced valves that control and prevent the flow of these fluids. One such valve is a double Block and Bleed Valve (DBB) ball valve. These DBB Ball Valves are designed to ensure zero leakage, safe maintenance and reliable performance.

How do Double Block & Bleed Ball Valves Work?

A double block and bleed ball valve is a special type of valve designed for additional protection. It has two sealing surfaces, known as “blocks”, which prevent fluid flow from both sides. Between these two blocks, there is a small cavity. This cavity consists of a “bleed” system that allows the trapped fluid or gas to be released safely.

Imagine two strong doors in a pipeline with a small safe place in the middle. Two doors are closed tightly to prevent flow from both directions. The location between them then becomes empty through a bleed outlet. This setup ensures that there is no leakage, even if a sealing surface fails.

In oil and gas plants, this system is very useful. Workers can perform maintenance on equipment without worrying about liquid leaks. It improves both safety and efficiency. This is why the DBB ball valves is used widely in pipelines, tank farms and offshore platforms.

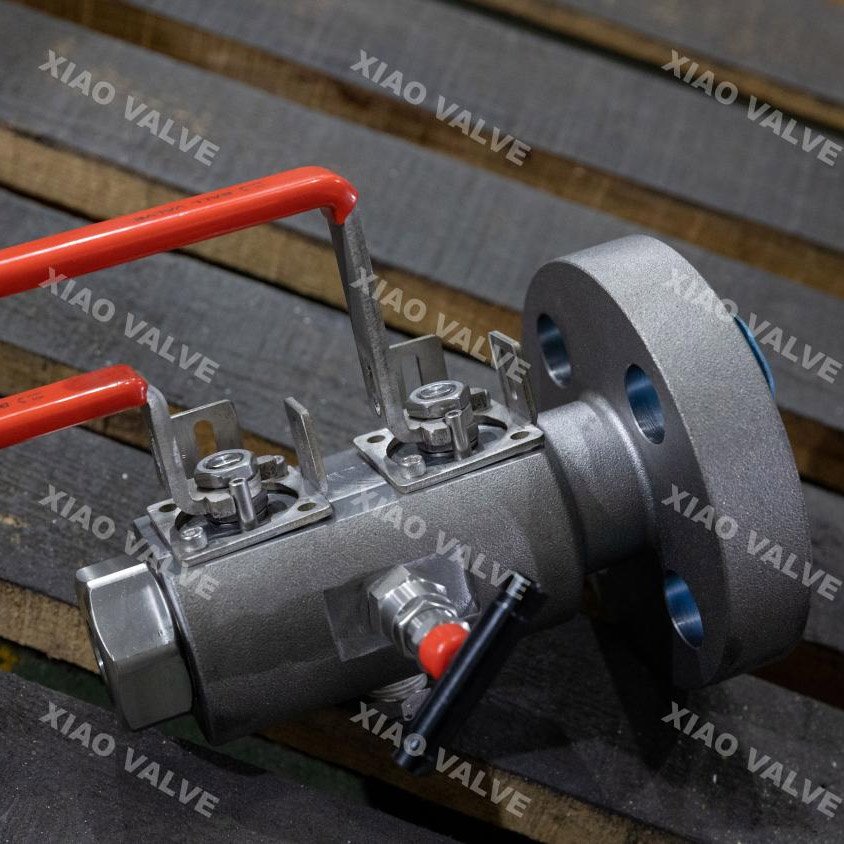

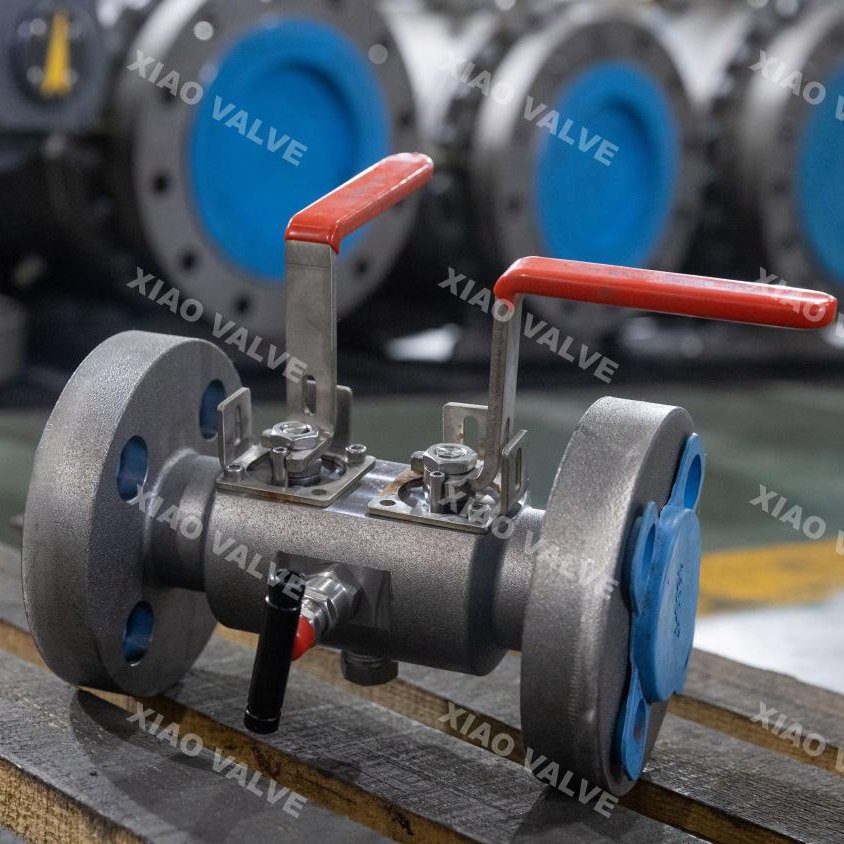

Premium DBB Ball Valves – Safe, Efficient, and Cost-Effective

Reliable Flow Control

Durable DBB ball valves are designed to deliver maximum safety and performance in demanding industries like oil, gas, and chemical processing. These trunnion Mounted DBB Valves provide true double isolation with two sealing balls and a bleed system placed between them. This ensures zero leakage, safe maintenance, and efficient system operation.

Special Seat Design for Better Sealing

The valves use a smart seat design with a flexible seal ring. For dependable sealing, the seal establishes a tight contact with the ball at low pressure. Long-lasting performance is ensured by the seal’s ability to expand without damage at high pressure.

Safety Features That Are Dependable and Fireproof

The valves’ fireproof construction ensures that they stay sealed even in the face of intense heat. Complete fire safety is ensured by standards such as BS 6755 and API 607, among others. Even under unusual pressure, the stem design keeps leaks and blowouts at bay.

Extra Protection Against Risks

To ensure system safety, these DBB valves include anti-static structures to prevent sparks and explosions. They also have lock systems to avoid misoperation, making them perfect for flammable and explosive environments.

Key Features of DBB Ball Valves

DBB ball valves come with many useful features. The most important one is their double isolation design, which makes them safer than standard valves. They also have a bleed function to release pressure from the cavity.

Another feature is their tight sealing capacity. The premium DBB valve is made to adhere to stringent international standards like ISO and API 6D. This indicates that they can withstand challenging circumstances and high pressure without leaking.

A lot of floating DBB Ball Valves enable fire-safe design. When the plant is fired, this feature makes sure the valve keeps working. Additionally, they are made to be easily operated, requiring little effort on the part of personnel to open or close.

Certain models can be fixed without taking the valve out of the pipeline since they are top-entry. During maintenance, this saves money and time.

DBB ball valve benefits in oil and gas applications

The oil and gas industry involves dangerous and expensive materials. Using a DBB ball valve gives many benefits.

- They provide increased security. Since the valve block flows from both sides and releases stranded pressure, it ensures that labour can work without risk.

- API 6D DBB Valve reduce leakage. This is important because even small leaks can cause safety hazards, environmental damage or loss of valuable product.

- These valves help in saving costs. Instead of installing two separate, different valves and a bleed system, a single DBB valve can work. It reduces the number of parts in a system and reduces the installation cost.

- They are versatile. They can be used in many different oil and gas functions such as refineries, gas pipelines, offshore rigs and storage facilities. Their credibility makes him a top option for engineers.

Types of DBB Ball Valves Available

There are different types of DBB ball valves to meet specific needs in the oil and gas industry. The most common ones include:

1. Trunnion Mounted DBB Ball Valves – These are designed for high-pressure systems. They use trunnion support, which keeps the ball in place and reduces operating torque. This makes them suitable for large pipelines.

2. Floating DBB Ball Valves – These are smaller and used for lower-pressure systems. The ball floats between the seats and uses line pressure to provide a tight seal.

3. Side Entry DBB Ball Valves – In this type, the body is assembled from two or three pieces bolted together. They are widely used and easy to maintain.

4. Top Entry DBB Ball Valves – These allow internal parts to be repaired or replaced without removing the valve from the line. This makes them great for situations where downtime is costly.

Materials are used for the DBB Ball Valve Manufacturing.

The performance of a DBB ball valve also depends on the materials used. Since oil and gas environments are harsh, the valves must be made with strong and durable materials.

Carbon Steel is often used for body construction. It provides strength and is suitable for many oil and gas applications.

Because it resists corrosion, stainless steel is the material of choice. It is utilized in a setting where fluids have the potential to corrode or destroy objects.

When a valve must withstand high pressure and extremely high temperatures, alloy steels are utilised.

Materials like PTFE, nylon, or elastomers are used to make seats and seals. These guarantee a tight seal and seamless functioning.

How to Choose the Right DBB Valve for Your Project

Choosing the right DBB ball valve is very important.

The first thing to consider is the pressure and temperature rating. Make sure the valve can handle the conditions of your system.

Look at the type of valve. For high-pressure pipelines, trunnion-mounted DBB valves are better. For smaller applications, an Oil and Gas Isolation Valve may be enough.

The material is also important. If your system carries corrosive fluids, stainless steel is the right choice. For general use, carbon steel may be sufficient.

Another factor is size and end connection. The valve should fit perfectly with your pipeline design. You should also check if you need a fire-safe or anti-static design, which are general requirements in the oil and gas industry.

Where to Buy Reliable DBB Ball Valves?

When it comes to buying DBB ball valves, quality and trust matter the most. Many companies make valves, but not all meet international safety and performance standards. That is why you need a reliable supplier.

XIAO Company is one of the most trusted manufacturers of high-quality ball valves. They provide a fire-safe DBB Ball Valve that meets global standards and delivers top performance.

They also offer excellent customer support and technical guidance. Whether you need a trunnion-mounted, floating, side entry, or High-Pressure DBB Valve, they have the right solution for your project. Choosing XIAO Company means choosing peace of mind, knowing your system is protected by reliable valves.

Recent Comments