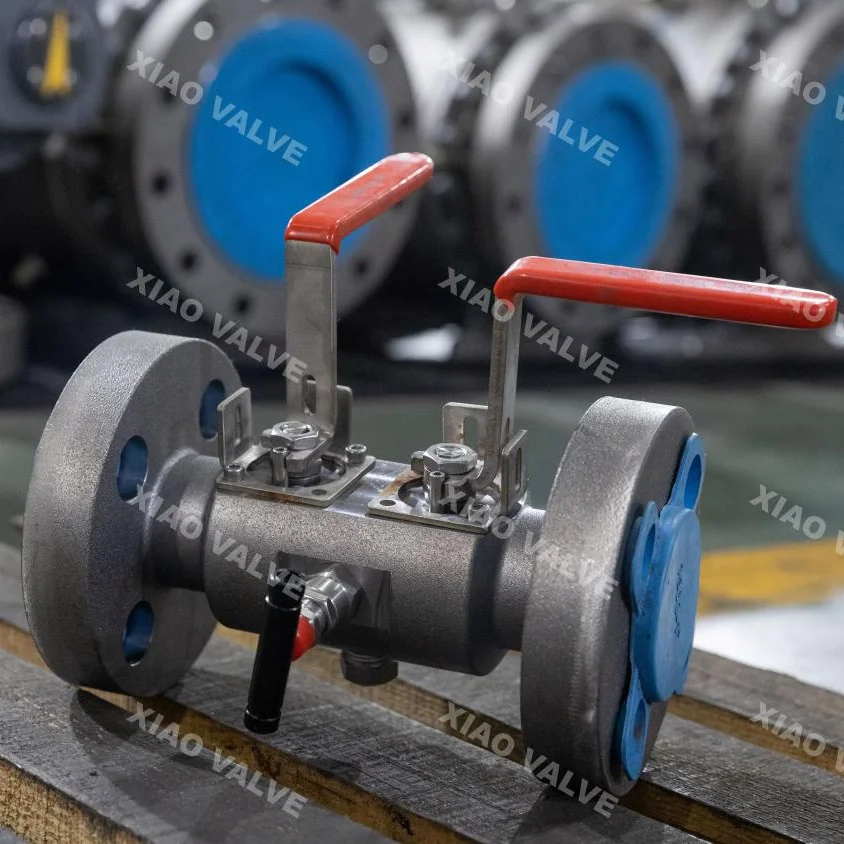

Double Block and Bleed Ball Valve

Choosing the right valve for your pipeline project is very important. It keeps your system safe and working well. One valve that stands out in many industries is the double block and bleed ball valve. It offers safety, control, and performance. But picking the wrong valve can lead to big problems like leaks or pressure loss. So, how do you know which one is right for you?

You understand what a double block and bleed (DBB) ball valve does. We will also talk about what to look for before you buy one.

What Does a Double Block and Bleed Ball Valve Do?

A floating ball valve design is special. It helps shut off the flow from both sides of the valve. Then, it releases any trapped pressure through a bleed system. This makes your system much safer. People often use it where leaks must not happen at all.

For example, imagine a long oil pipeline. If someone needs to fix part of it, they can close the valve on both sides. This blocks the oil from moving forward or backwards. Then, they open the bleed valve to drain what is left in the middle. This stops leaks and lets workers do their job safely.

Key Factors to Consider When Choosing the Right Valve

Before you buy a Pipeline isolation valve, you want to consider a few essential matters. These elements will help you choose the proper valve for your pipeline.

Look at the pressure score. Different pipelines have specific stress levels. Your valve ought to manage the strain of your machine with no leaks or breaks. Always check the valve’s stress class before buying.

Consider the fabric. DBB valves may be made from carbon steel, stainless steel, or other metals. If your pipeline incorporates water, chrome steel may be an excellent choice. If it includes chemical substances or oil, carbon, metallic or special alloys is probably better.

Check the temperature range. Some valves work well in hot environments. Others work better in cold places. Pick a valve that can handle the temperature your system usually has.

Consider the size and end connection. Your valve must fit your pipeline. Valves come in many sizes. Also, their ends can be flanged, threaded, or welded. Choose the one that fits your system best.

Look at the operation method. Some valves are turned by hand. Others use gear, electric, or pneumatic actuators. Pick what’s easy and safe for your team to use.

When you think about these five things—pressure, material, temperature, size, and operation—you’ll have a better chance of getting the right valve.

Types of Double Block and Bleed Ball Valves

There are different types of double block and bleed ball valves. Each one has a special use and design. Knowing the types can help you choose the best one for your pipeline project.

- The first type is the trunnion-mounted ball valve. This type has extra support for the ball inside. It is good for high-pressure systems because it reduces friction and wears less over time. If your pipeline deals with strong flow or heavy pressure, this is a good choice.

- The second type is the floating ball DBB valve. This type uses a ball that moves slightly inside the valve. It presses against the seats to stop the flow. This type works best in low to medium-pressure systems. It is simple and cost-friendly.

- Another type is the integrated DBB valve. It has all parts in one body. This makes it lighter and smaller. People use it in places where space is tight. It also reduces leak paths since there are fewer joints.

- There is also the modular DBB valve, which is made of separate parts put together. This type gives you more choices for customization. You can pick different materials or seat types to fit your system.

Each type of bleed valve system has its benefits. When choosing, think about your system’s needs and where you will use the valve.

Key Applications for DBB Ball Valves

High-pressure shutoff valves are used in many industries. They help stop leaks and make systems safe to work on. You will find those valves in oil and gasoline fields, chemical plants, power stations, and even water structures.

In the oil and gas industry, DBB ball valves are utilized in pipelines, refineries, and offshore rigs. Oil and gas ball valve helps isolate parts of the device for the duration of maintenance or testing. This makes certain workers live safely, and the environment is included.

In chemical flora, those valves manage the go with the flow of sturdy liquids or gases. They help prevent injuries resulting from leaks or mixing of chemical substances.

Power plants use DBB valves to handle steam and cooling water. The valves have to withstand excessive temperatures and pressure, so deciding on the proper one is very critical.

Even in water systems, DBB ball valves play a key role. They help in maintenance work without shutting down the whole system.

No matter the industry, if you need a valve that gives full shutoff and safety, a DBB ball valve is the right choice.

Finding a Reliable Manufacturer for Safety Block Valve

Once you understand what type of DBB valve you need, the next step is to find an accurate manufacturer. A precise organization will offer remarkable values, speedy shipping, and helpful support. This is where XIAO Company is available.

XIAO Company is the top manufacturer of ball valves. They make strong, safe, and smart valve solutions for all kinds of pipeline projects. Their valves go through strict tests to make sure they perform well under pressure and heat. You can trust their products to last long and work smoothly.

XIAO Company offers many types of double block and bleed ball valves. Whether you need trunnion-mounted or floating ball types, they have what you need. They also offer custom valves based on your project.

One great thing about XIAO is its focus on customer care. Their team helps you choose the right valve. They answer questions and solve problems fast. This makes your job easier.

Also, XIAO Company uses high-grade materials. Their valves meet top industry standards. That means less worry for you. Their prices are fair too, which helps you save money without losing quality.

If you want a trusted partner for your valve needs, XIAO Company is the name you can count on. With their help, your pipeline project will be in safe hands.

Recent Comments