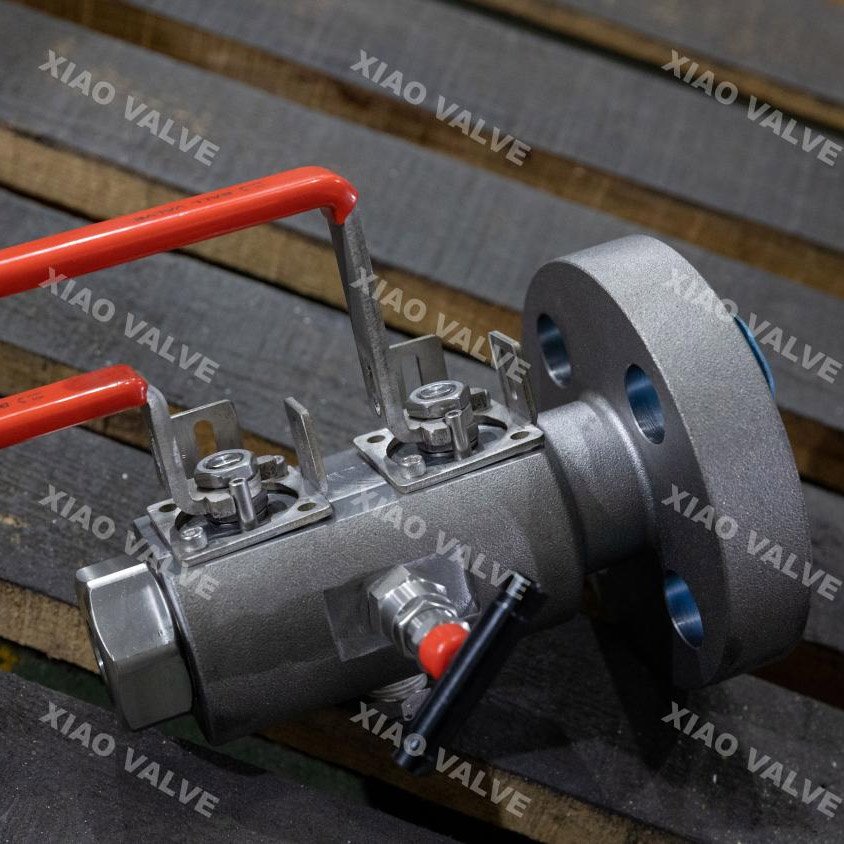

Flanged Ball Valve Manufacturer

When it comes to controlling the flow of liquids or gases in a pipeline, a strong and reliable valve is key. That’s why many industries choose flanged ball valves. These valves are known for their strength, easy operation, and tight sealing. A high-quality flanged ball valve manufacturer offers valves that last long, work well, and handle pressure without leaks.

We’ll explain about Industrial ball valve with flange ends, why it’s important, and what makes it durable and leak-proof. We’ll also explore the types of flanged ball valves, the materials and sizes available, and the industries that rely on them every day.

Types of Flanged Ball Valves

There are different types of flanged ball valves, and each one serves a special purpose.

The most common types include floating ball valves and trunnion-mounted ball valves. A floating ball valve has a ball that moves slightly to press against the seat and seal the valve. It’s great for low to medium pressure systems. On the other hand, a trunnion-mounted ball valve has extra support that keeps the ball in place. This type is perfect for high-pressure and large-scale systems.

Another way to group flanged ball valves is by the number of pieces. Some valves are made with one frame piece, at the same time as others come in two or three pieces. A one-piece valve is strong and compact. Two-piece flanged ball valves are easy to take apart and easy, making them ideal for systems that need normal care.

There are also exclusive quality connection standards like ANSI, DIN, or JIS. These requirements assist in ensuring the valve suits with other pipes and elements. Choosing the proper type depends on your system and the way you intend to apply the valve.

Key Features of Durable and Leak-Proof Flanged Ball Valves

A long-lasting and leak-proof flanged ball valve must have certain key functions.

- The ball itself should be made from a strong material like stainless steel. This allows it to resist rust and be put on over the years. A clean and polished ball also guarantees a decent seal with less friction.

- The valve seats and seals ought to be made from brilliant substances like PTFE (Teflon) or other special plastics. These substances can manage excessive temperatures and pressures without breaking down. They also help maintain the seal tight, which stops leaks.

- Another crucial characteristic is the robust valve frame. The body needs to be thick and well-forged, with no vulnerable spots. It must also suit pipe flanges perfectly to avoid gaps and ensure a decent fit.

- A super valve also has a blowout-proof stem, which means that the stem cannot be driven out of the valve even if the stress builds up. This adds more safety and reliability.

Benefits of Choosing a Trusted Flanged Ball Valve Manufacturer

Choosing a trusted flanged ball valve manufacturer brings many advantages.

You get high-quality, you may assume. A proper manufacturer follows strict requirements and assessments on every valve before it leaves the factory. This enables avoiding issues later.

A dependable manufacturer also gives robust warranties and after-income support. If something is going wrong, they’re there to assist. This builds consideration and saves money and time.

You also get get entry to to a wide variety of valve kinds, sizes, and substances. Whether you want a small valve for a water line or a large valve for oil and gasoline, a good high-pressure flanged valve manufacturer will have what you need.

Most importantly, trusted manufacturers provide custom solutions. If your mission has special wishes, they can design a valve only for you.

When it comes to your system’s protection and performance, choosing the proper flanged ball valve manufacturer makes all the difference.

Materials and Sizes Offered for Industrial Applications

Top flanged ball valves need to be crafted from the right materials to fit the application. Stainless steel is one of the maximum famous materials. It resists rust, warmth, and pressure, making it perfect for many industries. Carbon metal is likewise strong and value-powerful, often utilised in oil and gas.

For some programs, brass or PVC may be used, especially in low-pressure or non-corrosive structures. Some valves also come with special coatings to address chemical compounds or saltwater.

Sizes of stainless steel flanged ball valves vary from ½ inch to several inches wide. The right size relies on the pipe and the go with the flow requirements. A valve that is too small might also sluggish down the go with the flow. A valve that is too big may not be healthy or may cost more than expected.

Having many materials and size alternatives enables the value to suit the activity. This guarantees higher performance and a longer existence.

Industries That Rely on Flanged Ball Valves for Performance

Many industries rely upon flanged ball valves every day. In the oil and gasoline industry, these valves handle high-pressure fluids and gases. They need strong seals to forestall leaks and save your chances.

The chemical industry makes use of full port flanged ball valve to govern the flow of liquids that can be dangerous or corrosive. These valves should be leak-proof and fabricated from materials that resist chemical damage.

Water treatment plants also use flanged ball valves to control clean and dirty water. These valves assist in maintaining the machine secure and green.

In a power plant, steam and water flow underneath high pressure. Flanged ball valves help manage this float thoroughly.

Even food and beverage factories use those valves to transport liquids like milk, juice, or syrup. These industries need smooth, safe, and easy-to-clean valves.

From heavy industry to everyday uses, ANSI standard flanged valves play an essential role in ensuring that structures function smoothly.

Why Our Manufacturing Process Ensures Long-Lasting Quality

At XIAO Company, we accept as true in constructing valves that ultimately.

Our production method uses exceptional materials, modern tools, and careful assessments to make certain every valve meets the best requirements.

We begin with pleasant raw materials. Every piece of metal or plastic is tested before use. Then, we use superior machines to form every component with care. This ensures the parts are healthy and work easily.

Our crew follows a strict, exceptional management plan. Each valve is going through strain exams, seal tests, and energy assessments. We don’t ship any valve that doesn’t bypass every check.

We also listen to our clients. If a client wishes a special size, form, or strain rating, we will customise the valve to match the needs. This makes us exceptional from many different corporations.

With years of experience and a strong cognisance of best practices, our leak-proof pipeline valves are built to final, even in the hardest conditions.

Most Trusted Flanged Ball Valve Manufacturer

If you’re looking for a dependable flanged ball valve manufacturer, XIAO Company is a good choice. Known for high requirements, strong products, and exquisite service, they’re a top name in the industry.

We design and make a huge range of ball valves, which includes flanged, socket weld, threaded, and trunnion types. Our valves are used around the arena in oil and fuel, chemicals, energy, water, and many different fields.

What makes they different is our interest in elements. We take a look at each valve, use the highest quality materials, and deliver full aid earlier than and once you buy. Whether you need a widespread valve or a custom design, we’re prepared to help.

Our team is trained to recognise what you need and recommend the best solution. When you pick XIAO Company, you’re deciding on safety, top, and peace of mind.

Recent Comments